Embark on a journey into the heart of lithium battery cycle life. In this blog, the aim is to unveil how these power units stay robust over time. Delve deep into factors that influence their long-term functionality.

Understanding Battery Cycle Life!

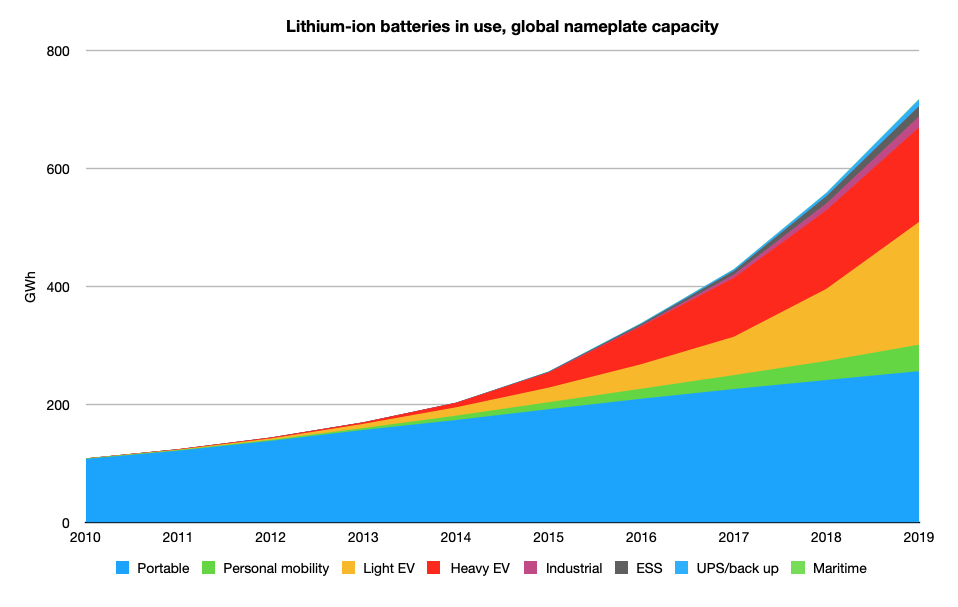

Image Source: circularenergystorage.com

Explanation of Cycle Life

In the world of power storage, lithium-ion battery life cycle refers to the number of full charge-discharge cycles a battery can handle before its capacity falls below 80% of the original. Typically, most lithium batteries can withstand between 300 to 500 cycles. Yet, factors like temperature, depth of discharge, and charging rate can influence the cycle life. Remember, every full charge and discharge counts as one cycle. Thus, preserving the battery’s cycle life prolongs its service years.

Importance of Battery Cycle Life

– Performance Reliability

Battery cycle life stands crucial for reliable performance. Greater cycle life means the battery can deliver consistent energy for longer periods. So, devices like smartphones, laptops, or electric vehicles maintain optimal operation over time.

– User Convenience

High cycle life ensures user convenience. Imagine a phone battery that lasts for a day instead of a few hours. Longer battery life reduces the frequency of recharging, thus, enhancing the user experience.

– Cost-Efficiency

Better cycle life equals cost-efficiency. High cycle life batteries need fewer replacements, resulting in significant cost savings over time. For commercial devices, improved cycle life means less maintenance and reduced total cost of ownership.

– Sustainability

Longer cycle life contributes to sustainability. Fewer battery replacements mean less electronic waste and more effective use of resources, supporting green technology initiatives.

– Lifespan Prediction

Understanding cycle life aids in lifespan prediction. Businesses use cycle life data to predict battery replacement schedules, ensuring smooth operation and maintenance of battery-powered systems.

– Load Capability

Cycle life impacts the load capability of the battery. High cycle life batteries can manage higher loads, enabling power-intensive operations in devices like electric vehicles and energy storage systems.

– Energy Density

A high cycle life indicates a battery with substantial energy density. This means it can store more energy per unit volume, a critical parameter for compact, portable devices.

– Power Capacity

Cycle life correlates with power capacity. Batteries with high cycle life tend to maintain their power capacity over time, providing steady output for longer periods.

– Scalability

Cycle life affects the scalability of energy storage solutions. Batteries with high cycle life are more suitable for scaling up in larger systems like grid storage or electric vehicle fleets.

– Energy Efficiency

High cycle life can enhance energy efficiency. Batteries with long cycle lives are typically more efficient, converting a higher percentage of input power into useful output.

Lithium Batteries: Types and Their Cycle Lives!

o Lithium-ion

Understanding the cycle life of a lithium ion battery cycle life is vital. One full charge and discharge count as a cycle. Normally, a Lithium-ion battery boasts around 300 to 500 cycles. Over time, each cycle degrades battery health, reducing capacity.

o Lithium Polymer

Lithium Polymer batteries, known as LiPo, have a shorter cycle life. Typically, these batteries offer 200 to 300 cycles. However, gentle charge and discharge can extend this lifespan. Fast charging, though, diminishes it rapidly.

o Lithium Iron Phosphate

Also known as LiFePO4 batteries, Lithium Iron Phosphate batteries offer up to 2000 cycles. They outperform other types in cycle life, due to their stable structure. Thus, they’re ideal for applications demanding high lifecycle counts.

o Lithium Titanate

Lithium Titanate batteries, referred to as LTO, can deliver over 10,000 cycles. A unique nano-technology and its quick recharge feature set LTO apart. Still, they have a lower energy density.

o Lithium Cobalt Oxide

Lithium Cobalt Oxide batteries, short for LCO, generally possess a cycle life of about 500 to 1000 cycles. Their high energy density makes them suitable for laptops and smartphones. However, safety concerns exist due to their reactive nature.

o Lithium Manganese Oxide

Lithium Manganese Oxide batteries, or LMO, have a cycle life close to 600 to 1,000 cycles. High thermal stability and enhanced safety are among their key features, but they come with a lower energy density.

o Lithium Nickel Manganese Cobalt Oxide

Lithium Nickel Manganese Cobalt Oxide batteries, known as NMC, provide about 1,000 to 2,000 cycles. With balanced power, capacity, and safety, NMC is preferred in electric vehicles and grid storage.

o Lithium Nickel Cobalt Aluminum Oxide

Lithium Nickel Cobalt Aluminum Oxide batteries offer between 500 and 1,000 cycles. NCA has a high energy density, perfect for power tools and electric vehicles. But, the cycle life is less compared to other types.

| Criteria | Lithium-ion | Lithium Polymer | Lithium Iron Phosphate | Lithium Titanate | Lithium Cobalt Oxide | Lithium Manganese Oxide | Lithium Nickel Manganese Cobalt Oxide | Lithium Nickel Cobalt Aluminum Oxide |

| Energy Density (Wh/kg) | 150-200 | 100-130 | 90-120 | 50-80 | 150-200 | 100-150 | 150-220 | 200-250 |

| Cycle Life (charge-discharge cycles) | 1200-1500 | 500-700 | 2000-3000 | 3000-7000 | 500-1000 | 1000-2000 | 1200-1500 | 500-800 |

| Charge Rate (C-rate) | 0.5-2C | 1-2C | 1-5C | 1-10C | 0.5-1C | 0.5-2C | 0.5-2C | 0.5-1C |

| Discharge Rate (C-rate) | 1-2C | 1-2C | 10-25C | 1-10C | 1-2C | 1-3C | 1-3C | 1-2C |

| Safety Level (1 low – 10 high) | 6 | 5 | 9 | 10 | 4 | 7 | 6 | 5 |

| Common Uses | Phones, Laptops | RC Models, Drones | Power Tools, E-Vehicles | EVs, Power Grids | Cameras, Mobiles | Power Tools, Medical Devices | Laptops, Power Banks | EVs, High-performance Devices |

| Cost (1 low – 10 high) | 6 | 7 | 8 | 9 | 5 | 6 | 7 | 8 |

Table on Lithium Batteries: Types and Their Cycle Lives!

Factors Impacting Lithium Battery Cycle Life!

o Charging Cycles

Every lithium battery goes through cycles. One cycle involves a full discharge followed by a full recharge. Ideally, a battery should provide 500 to 1500 cycles. However, cycle life depends on several factors, including temperature and discharge level. A higher temperature or deep discharge can reduce cycles, lowering the lifespan. Remember, proper maintenance can enhance cycle life.

o Depth of Discharge (DoD)

DoD, another crucial term, refers to the percentage of battery drained before recharge. Lower DoD (20%-50%) typically extends battery lifespan. Hence, to improve longevity, avoid complete discharge.

o Overcharge Impact

Overcharging can damage the internal structure, affecting cycle life. Therefore, always disconnect after full charge.

o Undercharge Impact

Just as overcharging harms, undercharging also limits the cycle life. Keeping batteries at a moderate charge level (50%-80%) ensures longer life.

o Temperature Variations

Batteries dislike extreme temperatures. Keeping them in a room-temperature environment (20-25°C) extends the cycle life.

o Physical Stress

Avoid dropping or bumping your battery. Physical stress can lead to structural damage, reducing cycle life.

o Voltage Fluctuations

Voltage spikes or drops can harm your battery, impacting cycle life. Use a stable power source for charging.

o Storage Conditions

For extended storage, keep the battery at a 50% charge state in a cool, dry place. This can help maintain cycle life.

o Material Degradation

Over time, battery materials degrade, affecting performance. High-quality materials and proper usage can slow this down.

o Internal Resistance

With time and usage, internal resistance increases, affecting cycle life. Proper battery care helps control this.

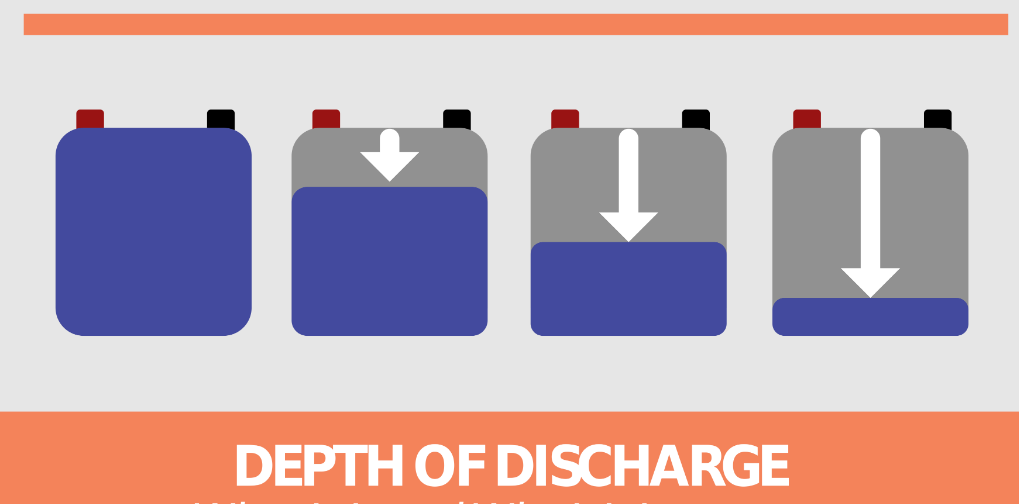

The Concept of Depth of Discharge (DoD)!

Image Source: www.foxtronpowersolutions.com

Definition and Importance of DoD

DoD indicates how much a battery gets used before recharging. A lower DoD, like 20% to 50%, means only a small part of the battery gets used. This can help in extending the battery lifespan, making DoD a critical factor in managing lithium battery cycle life.

Impact of DoD on Lithium Battery Cycle Life

Lowering DoD helps prolong cycle life. So, it’s better not to wait until the battery fully drains before recharging. For instance, charging when the battery is half full (50% DoD) can help. In the long run, this habit can extend the battery’s lifespan, answering the question of how long can a lithium-ion battery last without charging. Hence, properly managing DoD contributes to longer lithium battery cycle life.

Charging Patterns and Their Effect on Battery Cycle Life!

Best Charging Practices for Maximum Cycle Life

– Avoid Overcharging

To prolong the cycle life, cease charging at 80%. Overcharging can lead to heat and stress on the battery.

– Prevent Deep Discharge

Stop discharging at 20%. Too low a charge harms the battery’s life.

– Regular Charging

Batteries love frequent top-ups. Prolonged non-use harms the cell’s longevity.

– Moderate Temperature

Heat is a battery’s enemy. Keep them cool for a longer lifespan.

– Use Quality Chargers

Good chargers keep the power flow steady. Substandard ones can cause harm.

– Follow Manufacturer Guidelines

Each battery has specific needs. Following these can ensure longer battery life.

– Slow Charging

Rapid charging can harm the battery. Slower charging results in a longer lifespan.

– Avoid Fast Charging

Quick charges can stress the battery. Aim for a slower, steady charge.

– Partial Charging

Top up the charge regularly. Don’t wait for a full discharge.

– Uninterrupted Charging

Allow the charging process to complete. Interrupting can harm the battery. The charging cycle of lithium ion battery depends heavily on these best practices. Following these tips ensures the cycle life is as long as possible, bringing value and longevity to the device using the battery.

Effects of Overcharging and Undercharging

– Capacity Loss

Overcharging and undercharging reduces the battery’s capacity. This means less power when needed.

– Decreased Lifespan

Misuse of charging can reduce the battery’s lifespan. This results in more frequent battery replacements.

– Voltage Instability

Unstable voltages can arise from overcharging or undercharging. This instability can harm the device.

– Structural Damage

The battery structure can become damaged with improper charging. Damage leads to poor performance.

– Heat Generation

Too much or too little charge can create heat. Heat causes harm to both the battery and device.

– Risk of Explosion

In extreme cases, the risk of explosion increases. This is a serious safety hazard.

– Inefficiency

A misused battery becomes inefficient. It may not provide power when needed.

– Reduced Performance

The overall performance can decline with misuse. This can result in slower device operations.

– Inconsistent Power Output

Power output may become irregular. This inconsistency can harm the device.

– Elevated Self-discharge

Improper charging increases self-discharge. This means the battery drains faster, even when not in use. With these points in mind, the proper care of lithium-ion batteries becomes vital. Consistent and correct charging is key to the longevity of these powerful energy storage systems.

The Impact of Temperature on Lithium Battery Cycle Life!

o Decreased Capacity

High temperatures cause lithium batteries to lose capacity faster. Proper temperature regulation keeps batteries in top shape.

o Accelerated Aging

In contrast, each battery ages more rapidly in hot conditions. To increase battery life cycle, one must keep them cool.

o Increased Self-discharge

The rate of self-discharge rises when the temperature goes up. Control heat levels for a longer battery life cycle.

o Electrolyte Breakdown

An integral part of lithium-ion battery life cycle analysis involves electrolytes. Heat can cause these crucial parts to break down.

o Internal Resistance

High temperature raises internal resistance in batteries. This process reduces efficiency and drains battery life more quickly.

o Structural Deterioration

Unchecked heat leads to damage of the battery structure. Proper cooling mechanisms help maintain battery structure.

o Capacity Irreversibility

Excessive temperature leads to irreversible loss of capacity. Careful temperature management is a key aspect in battery life cycle calculation.

o Electrochemical Instability

The stability of the electrochemical reactions in the battery is disturbed by heat. Cooling systems maintain electrochemical stability.

o Thermal Runaway Risk

Overheated batteries risk thermal runaway, a destructive, self-feeding reaction. Regular temperature checks are necessary to prevent such mishaps.

o Reduced Efficiency

High temperatures lead to lower efficiency in batteries. Cool conditions foster improved battery performance.

Storage Conditions: A Key to Longevity!

Image Source: www.dnkpower.com

o Temperature Control

Proper temperature control is vital in extending battery life. Inappropriate temperatures cause performance issues and reduced battery life.

o Humidity Management

High humidity can damage batteries. Therefore, dry storage conditions are crucial for longevity.

o Pressure Stability

Varying pressures affect the battery’s internal mechanisms. Stable pressure conditions help batteries last longer.

o Light Exposure

Extended exposure to light can harm batteries. Store the batteries in dark places for better results.

o Vibration Avoidance

Constant vibrations can cause internal damage. Thus, batteries should be stored in steady places.

o Clean Environment

Dust and debris might infiltrate the battery casing. A clean environment enhances the lifespan of batteries.

o Isolated Storage

Batteries should be stored separately to avoid reactions. Each battery requires its own space for safety and longevity.

o Safe Ventilation

Proper ventilation prevents overheating and reduces risk. Safety comes first when storing batteries.

o Minimal Discharge

Batteries should maintain a small charge even during storage. Hence, a minimum charge is necessary for storage.

o Periodic Maintenance

Regular checks ensure batteries are in good condition. Timely maintenance helps prolong the lithium battery cycle life.

Battery Life Extension: Maximizing Your Lithium Battery Cycle Life!

o Proper Usage

Proper Usage lies at the heart of extending a battery’s cycle life. Don’t drain the battery completely. Instead, keep the charge levels between 20% and 80% for longevity.

o Regular Maintenance

Regular Maintenance plays a crucial role too. Keep the battery clean. Dirt and dust can impact performance over time.

o Optimal Charging

Optimal Charging matters as well. Charging too quickly or too slowly can harm the battery. Keep charging rates at lithium battery manufacturer’s recommended levels.

o Temperature Control

Temperature Control is essential for battery health. High temperatures can cause damage. So, store and use batteries in cooler environments.

o Avoid Deep Discharge

Avoid Deep Discharge to maintain battery life. A battery drained to 0% can suffer damage. Instead, aim to recharge at about 20% battery life left.

o Quality Chargers

Quality Chargers are key to maintaining a battery’s health. Chargers should be certified by recognized standards bodies.

o Balanced Load

Balanced Load is important for maintaining battery health. Overloading a battery can lead to overheating and damage.

o Stress Minimization

Stress Minimization is a crucial factor. Avoid exposing batteries to high-stress environments, which can harm their longevity.

o Timely Replacement

Timely Replacement can prevent damage to the device. When a battery’s capacity drops significantly, replace it.

o Manufacturer Guidelines

Follow lithium battery manufacturer guidelines always. Manuals usually contain precise instructions for maximizing battery life. Adherence to these rules can prolong the lithium polymer battery cycle life.

Understanding Battery Performance Indicators!

o Voltage

Voltage shows the electric potential difference in a battery. Higher voltage can deliver more power but can also lead to quicker discharge.

o Capacity

Capacity determines how much power a battery can store. More capacity means longer battery life between charges.

o Energy Density

Energy Density refers to the amount of energy a battery can store relative to its size. Batteries with high energy density can deliver more power for their size.

o Power Density

Power Density shows how quickly a battery can deliver its stored energy. Batteries with high power density can deliver more power at once.

o Discharge Rate

Discharge Rate is the speed at which a battery loses its charge. A lower discharge rate can extend battery life.

o Internal Resistance

Internal Resistance is a measure of how much a battery resists the flow of electricity. Lower internal resistance can lead to more efficient energy delivery.

o Load Capability

Load Capability is how much load a battery can handle at a time. Higher load capability allows for more devices to be powered simultaneously.

o Self-discharge Rate

Self-discharge Rate refers to how quickly a battery loses its charge when not in use. Lower self-discharge rates mean longer shelf-life.

o Temperature Stability

Temperature Stability refers to how well a battery performs in different temperatures. Batteries with good temperature stability can work well in various conditions.

o Cycle Efficiency

Cycle Efficiency measures how effectively a battery can be charged and discharged. High cycle efficiency can enhance the lithium sulfur battery cycle life.

Role of Material Science in Lithium Battery Life!

o Anode Composition

Choose high-performing anode materials, like graphite. High performance extends lithium battery cycle life. With time, research brings newer anode materials into light.

o Cathode Composition

Lithium cobalt oxide, a common cathode material, offers high energy density. Cathode materials define energy capacity and influence longevity of batteries.

o Electrolyte Properties

Electrolytes enable lithium ion movement, a crucial action for battery operation. Properly chosen electrolytes boost battery efficiency, influencing cycle life positively.

o Separator Efficiency

Separators act as safety barriers, blocking unwanted electric connections. More efficient separators aid longer battery lives. Innovation here is ongoing and promising.

o Structural Integrity

Structural strength safeguards battery internals. High structural integrity implies longer battery cycle life. Careful design ensures robustness against physical stresses.

o Material Degradation

Material degradation over time reduces battery efficiency. Less degradation equals longer battery life.

o Surface Morphology

Material surface characteristics can affect battery performance. Better morphology can lead to extended battery cycle life. Advanced microscopy helps in achieving desired surface properties.

o Crystal Structure

For lithium batteries, specific crystal structures promise better performance. Scientists work to develop materials with ideal crystal structures for longer battery life.

o Nano-technology Applications

Nanotechnology offers better control over material properties. Applied to lithium batteries, nanotechnology can boost battery efficiency and hence, its cycle life.

o Material Synthesis

Refining synthesis processes can lead to better battery materials. More efficient material synthesis translates into enhanced lithium battery cycle life.

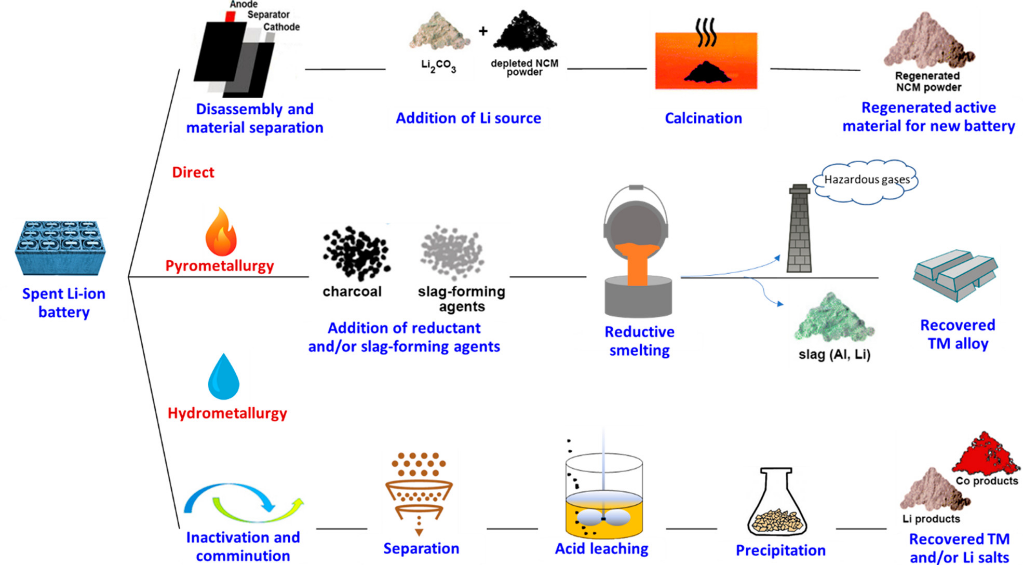

The Recycling Process of Lithium Batteries!

Image Source: pubs.acs.org

o Collection

Collecting spent batteries forms the first recycling step. Effective collection systems ensure maximum batteries enter the recycling process.

o Sorting

Accurate sorting helps identify reusable parts. Sorting separates batteries based on their type and condition, essential for lithium battery life cycle analysis.

o Shredding

Shredding breaks down batteries into smaller parts. Done in a secure environment, shredding can make material extraction easier.

o Neutralization

Neutralization process handles hazardous battery components. Ensuring safety, it prevents harmful leaks into the environment.

o Precious Metals Recovery

Valuable metals like cobalt and lithium are recovered. This step is vital as it conserves resources and promotes sustainability.

o Battery Grade Materials

Recovery produces battery-grade materials, ready for reuse. With efficient recovery, these materials can contribute to new battery production.

o Environmental Safety

Ensuring safety to the environment is a recycling priority. Best practices minimize harmful waste and promote a greener future.

o Regulation Compliance

Recycling process needs to comply with various regulations. Adherence to rules ensures safety and maintains trust in the process.

o Reuse Opportunities

Recycling creates opportunities for reusing materials. Reuse is an effective way to conserve resources and reduce manufacturing costs.

o Waste Minimization

Lastly, recycling minimizes waste. A significant amount of battery components can be reused, reducing the amount of waste produced. Effective recycling can extend lithium ion battery cycle life vs depth of discharge.

The Role of Battery Management Systems (BMS) in Longevity!

o Charge Control

A robust BMS leads to a longer lithium battery cycle life. One role is Charge Control. This duty maintains the correct energy inflow. Without it, overcharging harms the battery.

o Discharge Regulation

The next role is Discharge Regulation. It helps to prevent too much power drain from the battery. Another crucial duty is Thermal Management. It involves maintaining safe operating temperatures. High heat levels lead to rapid battery decay.

o State of Charge

State of Charge (SoC) is a vital parameter the BMS monitors. SoC determines the energy remaining in the battery. Knowing SoC helps avoid unexpected power loss.

o State of Health

Equally essential is State of Health (SoH). It measures the battery’s general condition. A lower SoH indicates a declining lithium titanate battery cycle life.

o Voltage Monitoring

Voltage Monitoring is crucial too. It ensures each battery cell operates within safe voltage levels. Neglecting the voltage monitoring can risk damaging the cells.

o Cell Balancing

Cell Balancing is another BMS function. Cells in a battery don’t always charge and discharge equally. Cell balancing evens out these differences.

o Fault Detection

The BMS is also responsible for Fault Detection. Identifying faults early prevents further damage. It also prolongs the battery life.

o Diagnostic Functions

Diagnostic Functions help understand the battery’s performance. It enables timely maintenance, which improves longevity.

o Communication Interface

The Communication Interface allows the BMS to relay information. Users can then monitor the battery’s performance and make informed decisions.

Lithium Battery Troubleshooting: Tips and Tricks!

Image Source: blog.epectec.com

o Visual Inspection

Proper troubleshooting can extend the lithium battery cycle life depth of discharge. One method involves a Visual Inspection. Look for obvious signs of damage, like bulging or leakage.

o Voltage Testing

The next step is Voltage Testing. A multimeter can determine if the battery produces the expected voltage. An abnormal voltage indicates a problem.

o Discharge Pattern

Examining the Discharge Pattern gives insight into battery health. An irregular pattern might suggest an internal issue.

o Temperature Monitoring

Temperature Monitoring is crucial. Excessive heat can cause severe battery damage. Always keep the battery in a cool, dry place.

o Re-calibration

Re-calibration can solve many battery issues. It aligns the battery’s charge level with the device’s battery meter.

o Clean Contacts

Next, clean the contacts. Dust and dirt on the battery terminals can impede energy flow.

o Isolate Issues

Isolate Issues by testing the battery in a different device. It helps to determine if the problem is with the battery or the device.

o Capacity Check

A Capacity Check measures the battery’s energy storage. A decrease in capacity means the battery is wearing out.

o Professional Assessment

Seek a Professional Assessment when necessary. Experts can provide valuable insights and solutions.

Conclusion

With firm steps, you’ve traversed the path of understanding lithium battery cycle life. Encompassing charge rates, discharge rates, and temperature impacts, the knowledge now in your hands equips you for better battery usage. Now, explore more enlightening topics at buzzupbattery.com , and continue the quest for knowledge.