It’s impossible to think about batteries without first seeing lithium-ion cells as their backbone. These battery cells have always been a top priority, whether for general or specialized purposes.

There are three common forms for batteries, which include the cylindrical, the square, and the lipo. As far as battery types go, the cylinder battery stands supreme among them.

Cylindrical lithium batteries with varying voltage and capacity have entered the market long before. They function similarly to standard battery cells and represent the most popular design for battery packs.

So, let’s dive deep into cylindrical cells in this post.

What Exactly Are Cylindrical Cells?

The cylindrical or tube-like form of the cylindrical battery was the inspiration for this unique name. It has a positive terminal on the cell cap and a negative terminal on the other end, and it is housed in a metal container.

Most battery manufacturers choose to produce cylindrical batteries. That’s because it is more economical and can be mass-produced more quickly.

Moreover, these cells are characterized by faster production times and lower kWh (kilowatt-hour) costs. By their nature, these cells lend themselves to various conventional factory automation processes.

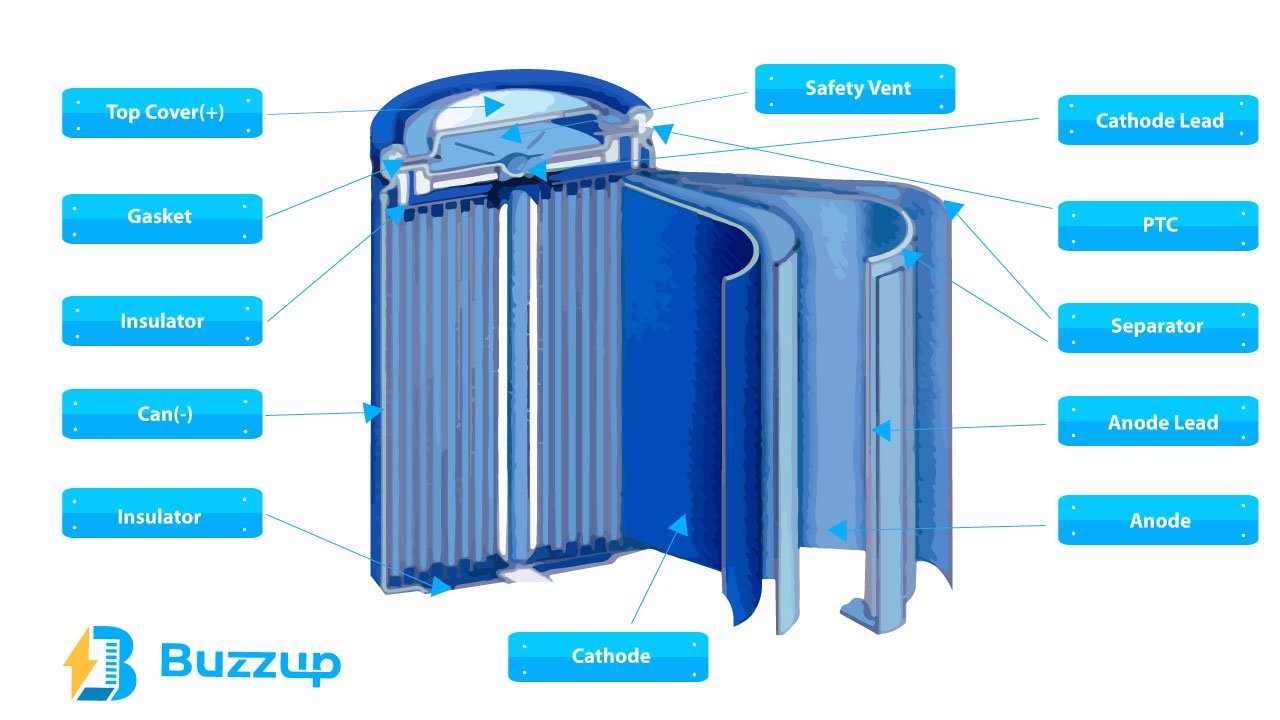

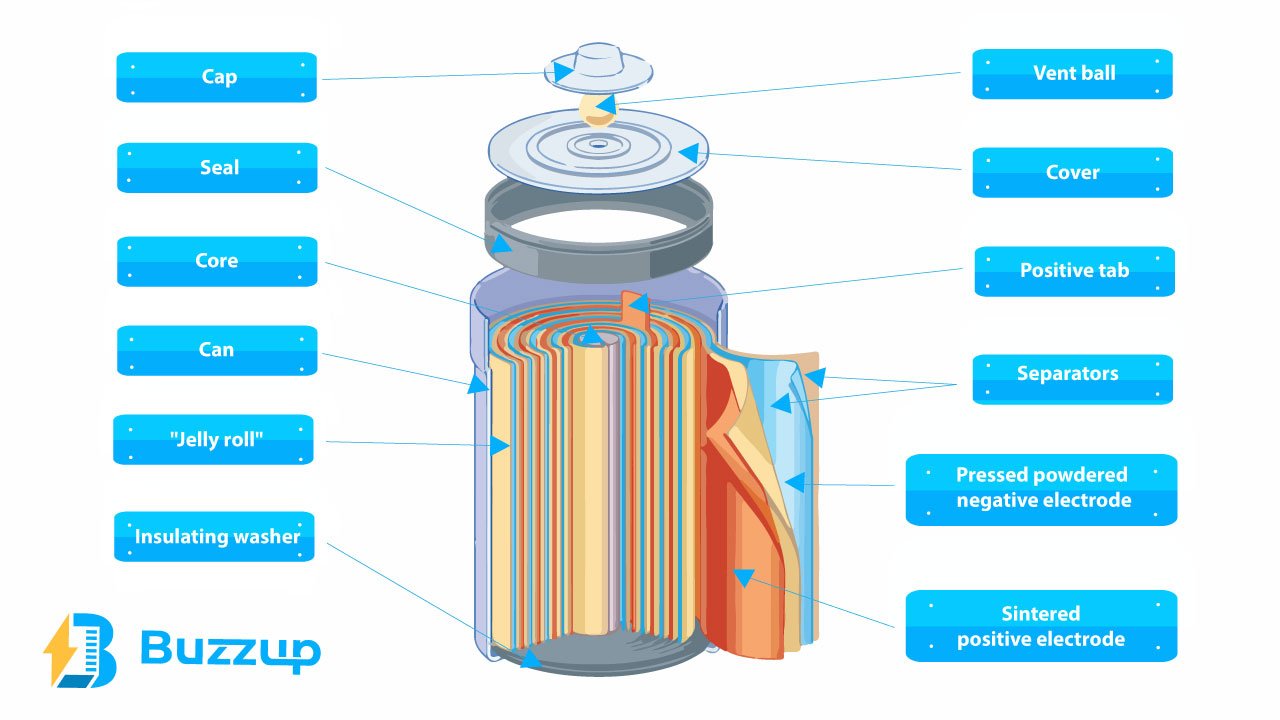

What Is the Structure of Cylindrical Cells?

Image Source: https://www.researchgate.net/figure/The-structure-of-a-cylindrical-lithium-ion-battery_fig2_272662523

The primary materials we find inside a cylindrical battery are the anode, cathode, and separators. Initially, an electrode sheet is made by fusing the bare cathode and anode material in a furnace to create a cylindrical cell.

A milling machine is used to reduce the particle size of all the materials. As a result, it reduces the effects of vibrations, temperature cycling, and expansion. All these effects can contribute to electrode material breakage.

How Are Cylindrical Cells Connected?

Manufacturers follow a unique method for connecting cylindrical cells. They use aluminum conductors to make the connections. These conductors can have varying thicknesses ranging from 0.25 to 1.0 mm.

What Are the Pros and Cons of Cylindrical Cells?

The cylindrical battery was the first lithium battery to be mass-produced by industry. Thus, there are benefits and drawbacks associated with this kind of cell.

Pros:

1) Reduced Bloating of Cells

First of all, these cells are ubiquitous in everyday life since they have many practical uses.

The electrolyte and internal pressure can both be dispersed uniformly due to the unique shape of cylindrical cells. Thus, the likelihood of leaks and cell swelling is reduced.

2) Highly Developed Cell

The first commercially used lithium-ion battery was the cylindrical battery. The cost of the pack is also comparatively inexpensive since the manufacturing process for cylindrical cells is already established after over twenty years of research.

3) Security

It’s also safe to work with cylindrical cells. Most other cells can burst if internal pressure increases to unsafe levels.

4) Unique Structure

A battery pack’s capacity and voltage can be increased by connecting cylindrical cells in parallel and series. Also, damage to one cell has little impact on the rest of the pack.

Cons:

1) Less Available Space

The energy density of a well-organized cylindrical-type cell is put to good use by including temperature management methods within the available volume.

However, due to the design’s cylindrical form, significant space is wasted between cells.

2) Weight

The specific energy of a battery pack is low since the cylindrical cell is often encased in a steel casing. As a result, this form makes it heavier than it needs to be.

What Are the Most Common Types of Cylindrical Cells?

Most applications make use of 18650, 21700, or 4680 battery cells. Cylindrical cells are the most developed type since their market has already been stabilized.

In particular, the 18650 and 21700 batteries are popular among customers.

How to Distinguish Between Cylindrical Cells?

Cylindrical cells come in a wide range of sizes, and that range is only expected to expand. Some are designed to work best in basic gadgets like toys and lamps, while others are more often used to power mobile electronics and hybrid or fully electric automobiles.

These cell types have these unique names based on their dimensions so that size and compatibility can be quickly determined.

The 18650 is a common type of cylindrical battery. Because of their lengthy lifespan, these batteries are ideal for usage in devices like torches, EVs, and gadgets. Likewise, 21700 is a different kind of cylindrical battery.

Battery capacity, manufacturing cost, and efficiency are where 4680 batteries really shine. Moreover, the battery’s capacity is five times larger compared to 21700.

Why Do 18650 Cylindrical Cells Have Greater Adoption?

Image source: https://www.lifepo4battery-factory.com/types-of-battery-cells-cylindrical-cell/

Given that all cylindrical batteries have the same exceptional qualities as lithium-ion batteries, picking the best one is challenging.

The 18650 battery type is the most popular and widely used cylindrical cell today. These batteries see heavier usage in industrial applications.

1) Durability

The life of a 18650 lithium battery, under typical usage conditions, may exceed 500 times. It makes them twice as durable as regular batteries.

2) Capacity

18650 cylindrical cells typically have a capacity between 1200 and 3400 mah.

3) Safety Features

These cells have been in research for decades. Thus, they come with an advanced safety mechanism.

Is It Possible to Make Cylindrical Solid-State Batteries?

We find a gel electrolyte in a lithium-ion battery. However, a solid-state battery uses a solid electrolyte. Electrodes made of solid materials are often ceramics, which may include oxides, phosphates, and sulfides.

Thus, it is challenging to create solid-state batteries in a cylindrical shape. Solid-state batteries may not be flexible enough to set into a cylindrical shape.

Where Can You Find Cylindrical Cells?

Many modern electronic equipment, including computers and power tools, use these cells. Moreover, Tesla cars utilize these batteries as well.

In contrast, some EV producers use prismatic cells. The design also makes them useful in space activities since lower air force would distort conventional cell types.

What Are the Safety Features of Cylindrical Cells?

Internal protection mechanisms found in most commercial cylindrical cells include:

- The Positive Temperature Coefficient (PTC) protects the cell from external shorts.

- The Current Interrupt Device (CID) safeguards the cells against overcharge.

Why Are Cylindrical Cells Preferable Over Pouch Cells?

Well, we will have to evaluate pouch and cylindrical cells. The cylindrical batteries will have a better yield rate and a higher degree of automation in their manufacturing.

Pouch batteries have a yield rate of over 90%, whereas cylindrical batteries may achieve above 95%.

Is There More Energy Storage in Cylindrical Cells?

Although they have less storage capacity for the energy, these cells are more potent. Thus, it denotes that these cells are more efficient at releasing their stored energy.

Therefore, cylindrical cells are the best option for demanding applications.

Final Thoughts!

In short, it is one of the most common types we find in a battery. It has strong cycle capacity, long life, and good cost efficiency due to its cylindrical shape.

Prismatic, in particular, has been the subject of discussion amongst experts as a viable alternative to cylindrical ones. These cells are somewhat costly and harder to acquire. Besides, they also take up more room in a battery pack.

Are you looking for cylindrical cells to buy at the best price available in the market? Well, Buzzup can help you! Buzzup can deliver different types of cylindrical cells worldwide.