What is Forklift Lithium battery & Why Buzzup Factory?

Forklift lithium batteries are recent years of innovations in technology in the Forklift industry. It means using lithium batteries to replace the traditional lead acid battery. Forklifts with lithium batteries can significantly decrease the charging time, reduce downtime, and increase warehouse or distribution center productivity. Also, lithium battery has higher power density, longer lifespan, no maintenance, and no toxic chemical released compared to lead acid battery.

Buzzup Factory has been manufacturing Forklift batteries since 2018. We are helping forklift manufacturers with their forklift battery projects with our professional knowledge of forklift batteries and our rich experiences in manufacturing forklift lithium batteries.

Also, we can supply you with the best solution forklift lithium battery according to your request, offering valuable support for your business needs. If you want a reliable forklift battery manufacturer in China, don’t hesitate to contact us today. We are the best choice for you.

Forklift Lithium battery By Voltage

Forklift Lithium battery has different voltage levels, and mainly we are offering 24V forklift lithium battery, 48V forklift lithium battery, and 80V forklift lithium battery. The different voltages of the forklift battery are all designed according to the different applications of the forklift types. The voltage level will impact the power output and the forklift’s working performance, so choosing the proper voltage lithium battery for your forklift is crucial. For example, heavy-duty forklifts need strong energy so that you will need an 80V forklift lithium battery.

Forklift Lithium battery By Application

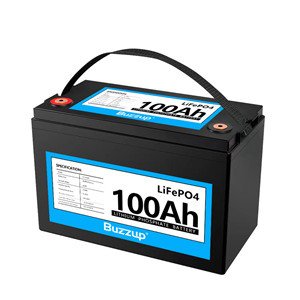

Forklift Lithium battery By Different Capacity

- Battery Type: Lithium-ion Battery

- Voltage: 24V

- Capacity: 90Ah

- Battery Cell Grade: Grade A+

- Battery Type: Lithium-ion Battery

- Voltage: 24V

- Capacity: 60Ah

- Battery Cell Grade: Grade A+

- Battery Type: Lithium-ion Battery

- Voltage: 48V

- Capacity: 38Ah

- Battery Cell Grade: Grade A+

- Battery Type: Lithium-ion Battery

- Voltage: 80V

- Capacity: 205Ah

- Battery Cell Grade: Grade A+

- Battery Type: Lithium-ion Battery

- Voltage: 48V

- Capacity: 410Ah

- Battery Cell Grade: Grade A+

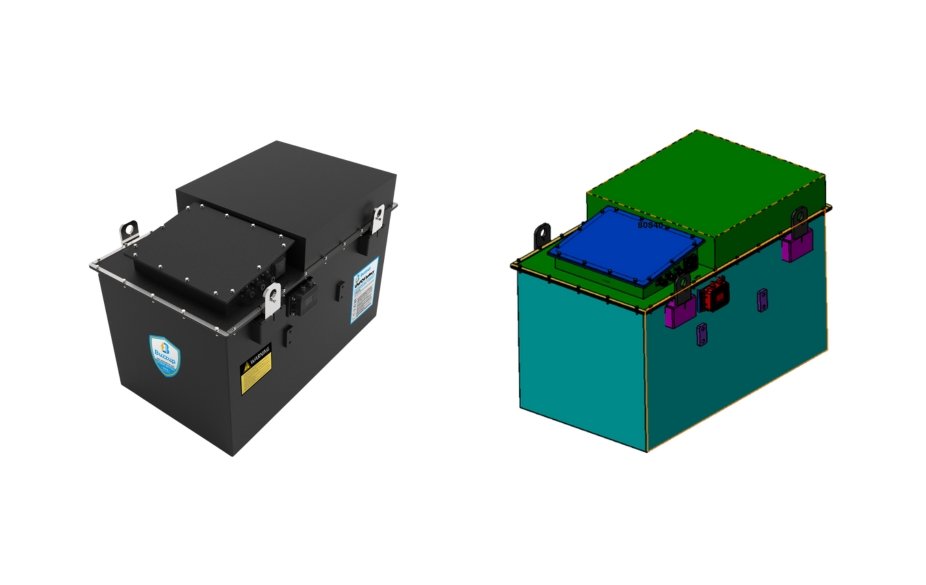

- Battery Type: Lithium-ion Battery

- Voltage: 80V

- Capacity: 840Ah

- Battery Cell Grade: Grade A+

- Battery Type: Lithium-ion Battery

- Voltage: 24V

- Capacity: 20Ah

- Battery Cell Grade: Grade A+

- Battery Type: Lithium-ion Battery

- Voltage: 24V

- Capacity: 20Ah

- Battery Cell Grade: Grade A+

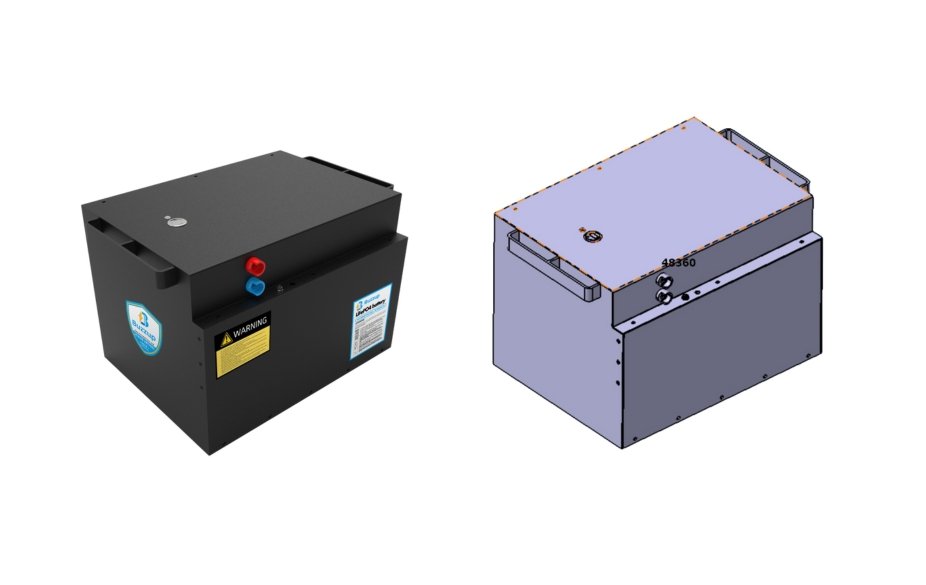

- Battery Type: Lithium-ion Battery

- Voltage: 48V

- Capacity: 360Ah

- Battery Cell Grade: Grade A+

Adventage of Forklift Lithium battery

Buzzup’s manufactured forklift lithium battery is with low maintenance requirements, and it significantly reduces your overall costs

Compared with traditional Lead-acid batteries, Forklifts’ Lithium Battery can support fast charging. It will help to reduce downtime and let the warehouse process quickly.

Buzzup factory’s forklift lithium batteries are ultra-safe, they do not contain any toxic chemicals. Also, less risk to get fire or get explosions compares with lead-acid forklift batteries.

Forklift lithium battery has strong power density and a much longer lifespan when compared with the exact size of forklift lead acid batteries.

Grade A LiFePO4 Automative Grade A Cell

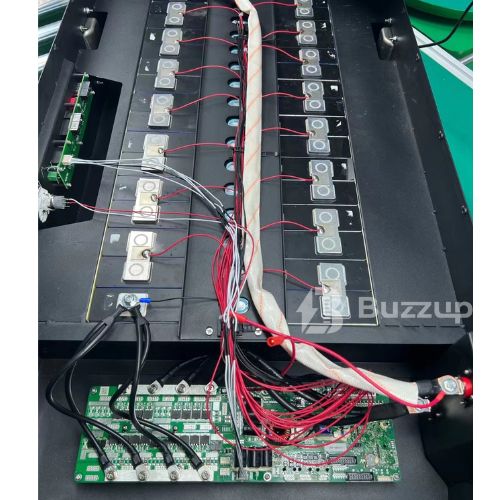

Buzzup factory promises will only adopt automotive grade A cells to manufacture forklift lithium batteries for your business. Used or second-hand LiFePO4 battery cells will cause inconsistency of the voltage problem, shorter lifespan, unqualified quality, and unsafe.

As a leading Forklift lithium battery manufacturer in China, we always supply our customers with first-tier LiFePO4 battery cells brands like EVE and CATL. We have a long-term relationship with them. So there is no double. You will get the very qualified and Grade A LiFePO4 battery cell in your forklift lithium battery.

Customized Forklift Battery Solutions

Due to the different types of Forklift applications, each forklift had different types and space for lithium batteries. So most forklift batteries need to be customized to fit the forklift correctly.

Buzzup can supply you with various solutions to customize your forklift lithium battery. Whether you are searching for lithium batteries to fit your refurbished forklifts or planning to find the right forklift lithium battery manufacturer to replace your lead acid forklift batteries, Buzzup is the best partner to work with.

Especially on most lead acid replacement forklift batteries, Buzzup knows how to control the weight so that the forklifts can work well when it is lead acid forklift or how to add an external LCD screen to monitor the lithium battery.

- To fit different applications of the forklifts.

- Customize 24V 48V 80V 96V Voltage

- Customized BMS, current.

- Lead Acid weight different control

- Forklift chargers with Fast charging Functions

- etc

Buzzup Project on Customize Forklift Lithium Battery

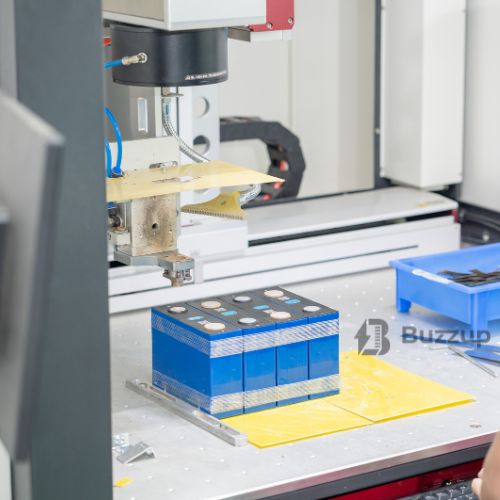

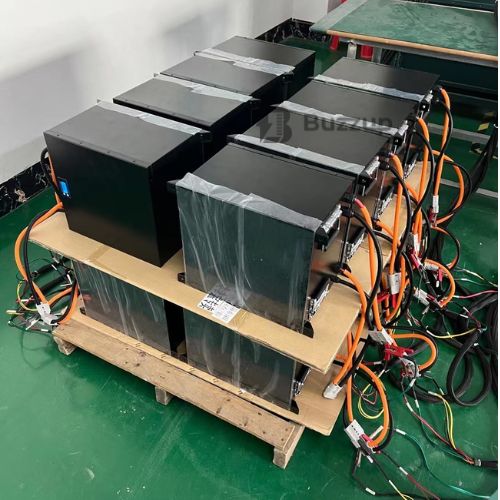

Buzzup Factory Forklift Lithium Battery Manufacturing View

- Factory Overview

| Model | Nominal Voltage | Nominal Capacity | Energy (KWH) | Dimension (L*W*H) | Weight KG(lbs) | Continuous Charge | Continuous Discharge | Max Discharge | Charging Time | Casing Material | Rating |

| 24V | |||||||||||

| CP24105 | 25.6V | 105Ah | 2.68KWH | 650*200*540mm | 26KG | 50A | 100A | 200A | 2.5h-3.5h | Steel | IP67 |

| CP24210 | 25.6V | 210Ah | 5.3KWH | 750*170*535mm | 67.5KG | 105A | 210A | 420A | 2.5h-3.5h | Steel | IP67 |

| CP24160 | 25.6V | 160Ah | 4.09KWH | 560*165*510mm | 37KG | 80A | 160A | 320A | 2.5h-3.5h | Steel | IP67 |

| CP24280 | 25.6V | 280Ah | 716KWH | 810*212*645mm | 87KG | 140A | 280A | 560A | 2.5h-3.5h | Steel | IP67 |

| CP24315 | 25.6V | 315Ah | 8.06KWH | 750*320*500mm | 72KG | 160A | 315A | 630A | 2.5h-3.5h | Steel | IP67 |

| CP24560 | 25.6V | 560Ah | 14.33KWH | 825*485*624mm | 127.2KG | 140A | 560A | 1120A | 2.5h-3.5h | Steel | IP67 |

| 36V | |||||||||||

| CP36210 | 38.4V | 210Ah | 8.06KWH | 750*320*500mm | 72KG | 110A | 210A | 420A | 2.5h-3.5h | Steel | IP67 |

| CP36280 | 38.4V | 280Ah | 10.75KWH | 666*465*345mm | 222KG | 140A | 280A | 560A | 2.5h-3.5h | Steel | IP67 |

| CP36315 | 38.4V | 315Ah | 12.09KWH | 988*689*635mm | 108KG | 160A | 315A | 630A | 2.5h-3.5h | Steel | IP67 |

| CP36420 | 38.4V | 420Ah | 1613KWH | 836*829*635mm | 144KG | 210A | 420A | 840A | 2.5h-3.5h | Steel | IP67 |

| CP36560 | 38.4V | 560Ah | 21.5KWH | 666*465*550mm | 285KG | 280A | 560A | 1120A | 2.5h-3.5h | Steel | IP67 |

| 48V | |||||||||||

| CP48210 | 51.2V | 210Ah | 10.75KWH | 950*370*550mm | 72KG | 105A | 210A | 420A | 2.5h-3.5h | Steel | IP67 |

| CP48280 | 51.2V | 280Ah | 14.33KWH | 800*520*450mm | 216KG | 140A | 280A | 560A | 2.5h-3.5h | Steel | IP67 |

| CP48300 | 51.2V | 315Ah | 16.12KWH | 728*350*530mm | 142KG | 160A | 315A | 630A | 2.5h-3.5h | Steel | IP67 |

| 72V | |||||||||||

| CP72280 | 73.6V | 280Ah | 20.60KWH | 666*465*550mm | 183KG | 140A | 280A | 560A | 2.5h-3.5h | Steel | IP67 |

| CP72315 | 73.6V | 315Ah | 23.18KWH | 953*700*736mm | 207KG | 160A | 315A | 630A | 2.5h-3.5h | Steel | IP67 |

| CP72420 | 73.6V | 420Ah | 30.91KWH | 938*798*778mm | 276KG | 210A | 420A | 840A | 2.5h-3.5h | Steel | IP67 |

| CP72560 | 73.6V | 560Ah | 41.21KWH | 810*650*550mm | 366KG | 280A | 560A | 1120A | 2.5h-3.5h | Stee | IP67 |

| 80V | |||||||||||

| CP80280 | 80V | 280Ah | 22.40KWH | 905*812*475mm | 325KG | 160A | 315A | 630A | 2.5h-3.5h | Steel | IP67 |

| CP80420 | 80V | 420Ah | 33.60KWH | 815*740*635mm | 435KG | 210A | 420A | 840A | 2.5h-3.5h | Steel | IP67 |

| CP80560 | 80V | 560Ah | 44.80KWH | 1005*765*650mm | 455KG | 280A | 560A | 1120A | 2.5h-3.5h | Steel | IP67 |

Related Product

Buying Guide For Lithium Forklift Battery

This is calculated by multiplying volts by the Amps and then dividing it all by 1000.

A forklift battery is designed to last an entire eight-hour shift on a full charge, but this can vary based on the age of the battery and how hard the equipment is working. A truck that doesn’t travel much doing minimal lifts might get twelve hours off one charge.

Yes, lithium forklift batteries can be partially charged without causing damage. They have a high tolerance for partial charging and can be charged at any state of charge without negatively affecting their performance or lifespan. This flexibility is one of the advantages of lithium-ion technology.

Maintenance requirements for lithium forklift batteries are minimal compared to traditional lead-acid batteries. Generally, they do not require watering, equalizing charges, or regular cleaning. However, it’s important to follow the manufacturer’s guidelines for charging and storage, and to perform periodic checks for any signs of damage or abnormal behavior.

Lithium forklift batteries are designed to operate within a wide temperature range, but extreme temperatures can affect their performance. Extreme cold can reduce the battery’s capacity temporarily, while extreme heat can decrease its lifespan. It’s recommended to consult the manufacturer for specific temperature recommendations and to implement any necessary measures to protect the battery in extreme conditions.

Initially, lithium forklift batteries are more expensive than traditional lead-acid batteries. However, when considering the longer lifespan, reduced maintenance costs, and increased efficiency, lithium forklift batteries often provide a lower total cost of ownership over their lifetime.

Li-ion batteries consist of largely four main components: cathode, anode, electrolyte, and separator.