As the globe moves toward a more environmentally friendly and sustainable future, there has been a dramatic increase in the need for smart and clean power storage methods. These days, Li-based batteries are used extensively for the purpose of storing alternative forms of energy and providing power to electric vehicles.

Two cathode chemistries within the field of Li batteries have received much attention: Among the several battery compositions making waves in the industry, Lithium Iron/Ferrous Phosphate (LFP) and Lithium Nickel Manganese Cobalt Oxide (NMC) stand out. Compared to ordinary batteries, LFP batteries have better security and a wider temperature range at which they may be used. The higher energy content and improved power output of NMC-based batteries render them well-suited for high-performance applications.

Cost, energy density, longevity, and safety factors are only a few of the factors that should be taken into account while deciding between LFP and NMC. Each kind of battery has its own benefits and drawbacks, adaptable for diverse applications, from electric cars to renewable energy storage.

This article will explore the characteristics and applications of the two batteries, shedding light on their key differences and benefits.

Decoding The Chemistry OF LFP AND NMC Li-Ion Battery

Before we explore their distinct traits, let’s get a handle on these battery formulations. Working in harmony, the anode, cathode, and electrolyte collaborate to fuel the battery. Ions are transported through a separator by an electrolyte, ultimately arriving at the cathode or anode, where they release their stored energy as electrons.

- LiFePO4 is the cathode ingredient that powers the LFP battery. This stable and reliable chemistry provides long cycle life and high durability. LFP cathode compound guarantees higher security and thermal stability by decreasing the potential for thermal runaway.

- Nonetheless, “LiNiMnCoO2” serves as the crucial cathode ingredient in NMC tech batteries. This chemistry outperforms lithium batteries in terms of energy density, meaning more power can be stored in the same amount of space. .

The cathode chemistry significantly impacts the performance and properties of these batteries. Whether it’s the enhanced energy richness and power capabilities of NMC or the longer cycle life and dependability of LFPs, cathode chemistry plays a significant part in determining these battery types’ overall features and functioning.

Specifications: LFP VS NMC

Specifications |

LFP |

NMC |

| Voltages | 3.20 and 3.30V nominal; 2.5 to 3.65V/cell average operational range | Nominal 3.60V, 3.70V; Common Operating Range 3.0–4.2V/Cell |

| C-rate Charge | Charging at 1C typically takes 3 hours and produces a voltage of 3.65V. | The normal charge time is 3 hours at 0.7-1C and 4.20-4.30V. Battery life is shortened by charge currents exceeding 1C. |

| Energy density or specific capacity | 90–120Wh/kg | 150–220Wh/kg |

| Lifespan | Higher than 2000 (in terms of discharge depth and temperature). | 1000–2000 (depending on temperature and discharge depth) |

| C-rate discharge | Some 1C and 25C temperatures; 40A bursts for 2 seconds; a cutoff voltage of 2.50V (less than 2V is harmful). | 1.50V cutoff; 2C feasible on certain cells; 1C maximum |

| Thermal runaway | 270°C (518°F) Totally risk-free even when fully charged. | Average of 210 degrees Celsius (or 410 degrees Fahrenheit). A high charge facilitates thermal runaway. |

| Applications | EVs, ESS, etc. | E-bikes, EVs, industrial and medical/health devices |

Shedding Light On The LFP Battery

LFP, short for Lithium Ferrous Phosphate, is a type of material commonly used in lithium batteries. In addition to its extended cycle life, it is renowned for its exceptional level of safety and stability. The batteries have lower compact energy than other Li-based compositions, but their enhanced thermal stabilization techniques show resistance to thermal runaway and prevent safety risks.

The Li-PO structure provides inherent stability making these batteries less prone to degradation over time. Due to these features, these batteries are a great option for use in specific areas where safety is a primary concern. Some examples of such applications are portable electronics, electronic bikes and vehicles, and sustainable energy solutions.

LFP Batteries – Advantages and Disadvantages

Globally, there has been a lot of interest in these batteries in recent years because of their security and reliability. Let’s begin with the benefits and drawbacks, which will provide helpful insight into the capabilities and limits of these batteries.

LFP BATTERIES ADVANTAGES

- Improved Protection: The batteries are well-known for having better security characteristics than other types of batteries. Because of their iron phosphate structure, they are less likely to overheat and cause thermal mishaps. This characteristic makes batteries preferred for applications where safety is paramount, notably in critical environments like electric mobility solutions.

- Extended Durability: These batteries boast an extended lifespan, allowing them to endure more charge-discharge cycles before exhibiting noticeable wear. This impressive longevity makes batteries a trustworthy choice for power storage solutions necessitating frequent charging and discharging, contributing to cost-effectiveness.

LFP BATTERIES DISADVANTAGES

- Minimizing Energy Density: This battery exhibits a comparatively reduced energy density than other Li-ion formulations, showing that they are less efficient energy stores overall. Therefore, LFP batteries may not be the best option for gadgets or vehicles requiring space or range.

- Limited High-Rate Performance: These batteries often demonstrate limited high-rate performance, meaning they may struggle to deliver high power output in short bursts. This limitation can affect applications that demand rapid acceleration or quick charging requirements.

NMC Batteries: Powering The Future

NMC, an acronym for “Lithium Nickel Manganese Cobalt Oxide,” is a type of cathode ingredient commonly used in Li-ion batteries. It is characterized by its composition, which includes a formulation of nickel, manganese, and cobalt. Lithium NMCs offer a balanced combination of compact energy, power performance, and stability.

These batteries are known for their ability to provide longer-lasting power and to store energy efficiently. Because of their many valuable qualities and adaptability, NMC power sources are increasingly employed in fields as diverse as electric cars, handheld gadgets, and renewable energy storage systems.

NMC Battery Advantages and Disadvantages

Let’s explore these batteries’ positive and negative aspects, providing insights into their strengths and limitations across various applications.

NMC BATTERIES ADVANTAGES

- Impressive Energy Density: The batteries excel in providing a remarkable energy density, surpassing other lithium-ion chemistries. This translates to more energy stored per unit weight or volume, enabling longer-lasting power and increased range for electric vehicles. NMC batteries also allow for more compact and lightweight designs in portable electronics.

- Excellent Power Performance: This battery demonstrates exceptional power capabilities, allowing it to deliver and accept high power levels efficiently. This property is especially useful for products like electric cars and high-demand portable electronics since they make use of quick charging and draining of the battery.

NMC BATTERIES DISADVANTAGES

- Thermal Stability Concerns: Such batteries are more susceptible to thermal runaway than other Li This means that careful thermal management and safety measures must be implemented to prevent overheating and potential safety hazards, especially during high-stress or extreme temperatures.

- Cost Considerations: Such batteries tend to be more expensive to manufacture than certain alternative lithium-ion chemistries. The inclusion of valuable metals like nickel, manganese, and cobalt, along with complex production processes, can contribute to higher production costs which may impact the overall affordability and accessibility of NMC battery-based systems.

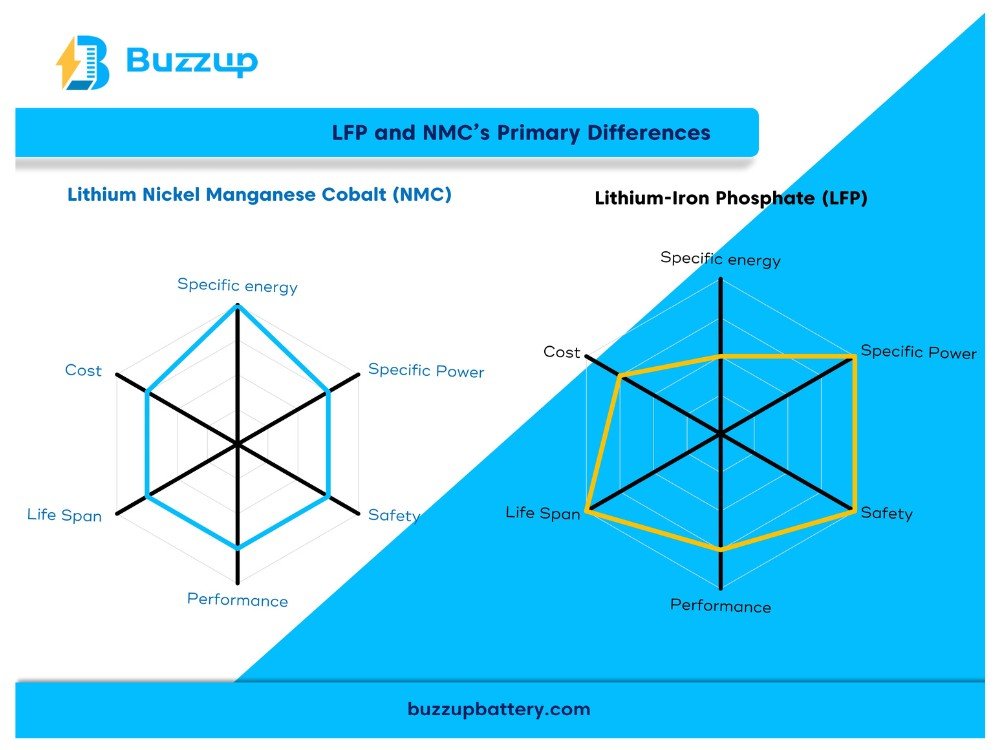

LFP and NMC’s Primary Differences

· Qualities In Terms Of Performance

The two batteries are equivalent in terms of their capacities overall. Both may be found in sizes ranging from a little too large to accommodate any energy storage need. Most households’ storage demands are about 10 kWh; NMC and LFP batteries can handle that. There are subtle distinctions to be made, however.

While Li-NMC batteries are more resilient to cold temperatures, LiFePO4 cells are more efficient and perform better at lower charge levels. These differences may become more pronounced at extreme temperatures or in certain application scenarios.

· Lifespan And Decline

Batteries gradually lose some of their capacity to store energy due to degradation. Due to their slower aging rate, lithium batteries exhibit exceptional performance in this specific scenario, outperforming nickel-rich batteries. Because of this, lithium-based batteries can store and release more power for a longer period of time.

Battery performance also plays a significant role in determining its lifespan; as a result, it’s crucial to consider the warranty and opt for reputable solutions and installations.

· Safety Considerations

When deciding on battery technology, it’s crucial to prioritize safety. The lithium cell technology has an inherent safety benefit due to the chemistry’s stability, particularly at higher temperatures. Since lithium batteries can handle greater power demands without overheating, they pose less of a fire hazard.

While NMC-based batteries do not pose any intrinsic danger, their susceptibility to damage may worsen if used in hostile environments or treated violently. Always use trained experts who prioritize safety throughout handling and installation for peace of mind.

· Life Cycle

When comparing NMC and LFP, the former battery generally provides 800 cycles while the latter offers more than 3000. The LFP battery has a cycle life of up to 6000 cycles when used and maintained correctly.

Because of their extraordinary lifetime, the LiFePO4 cell technology is a great option for uses in which high performance over a long period is required. The remarkable longevity of lithium-based batteries assures long-term dependability and cost-effectiveness, decreasing the need for frequent replacements and minimizing environmental impact, whether they are used for smart power storage or electric cars.

· Maintaining A Healthy Environment

LFPs outperform NMCs when it comes to finding eco-friendly alternatives. Cobalt and nickel, used in NMC batteries, are recognized toxins that may have harmful impacts on the environment. On the other hand, lithium composition batteries use components that are safer for humans and the environment.

By opting for LFP (LiFePO4) batteries, you contribute to a greener future by reducing the potential harm associated with the extraction, production, and disposal of hazardous materials. These batteries align with the aim of sustainable energy storage systems, making them a favorable choice for eco-conscious individuals and industries.

· Temperature Resilience

Compared to NMC chemistry, LFP batteries are more reliable when the temperature around them fluctuates. Because of its broad operating range, typically between -4.4°C and 70°C, LiFePO4 batteries may function successfully in various temperatures. Since EVs need to operate reliably in various conditions, these LFP ones are an excellent choice for powering such devices.

· Cost Factors

The cost of the battery may influence the model selected. The NMC formulation is more budget-friendly than the LFP one. This phenomenon may be partially explained by the market’s widespread usage of nickel-rich batteries, which has led to economies of scale and cheaper costs. Due to its larger dimensions, the LFP power source may need more installation labor and supplies. However, the cost difference between these two lithium-ion batteries is inconsequential for most residential solar power systems.

· Durability and Reliability

A battery’s value is determined by its purchase price and the entire amount of energy it generates during its lifespan. So, Li-cell batteries are more cost-effective in the long run since they deteriorate slowly. Although NMCs are cheaper upfront, LFP batteries last far longer and are the superior bargain.

· Charging and Discharging

Due to their unique charge-discharge curves, NCM and LFP batteries provide different results when measuring the state of charge (SOC). Due to the significant voltage dependence of SOC in NCM batteries, accurate SOC diagnostics are possible. However, accurately calculating SOC may be difficult because of the LFP battery’s flatter charge-discharge curve.

In 2020, researchers Yuliya Preger et al. demonstrated the advantages of LFP batteries in a study published in the Journal of the Electrochemical Society. Compared to NCMs, LFPs provided almost five times as many charge cycles, displayed greater round-trip efficiency, and degraded less quickly, particularly when subjected to high temperatures and rapid charging rates. Thus, LFPs prove superior for high-rated vehicles and rapid recharging capabilities. The performance and applicability of both types of batteries are distinct due to their distinct charging and discharging properties.

The Bottom Line – LFP OR NMC – Which One To Consider?

When deciding between these two batteries, it’s important to take into account your specific requirements. LFP cells are more cost-effective to produce initially, making them more competitive in the commercial market. LiFePO4 batteries provide operational benefits such as a broader temperature range and fewer transportation needs. They are safer and last longer than the alternatives.

However, a battery like NMC could be more accessible and maintain its performance. These batteries’ small form factor might be advantageous in tight quarters. The final choice should be based on criteria, including budget, performance, expected lifetime, and installation space.