The aim is to dive into the heart of lithium battery energy density. We will shed light on its meaning, importance, measurement units, and scientific aspects, to give you a well-rounded understanding of this powerful energy resource.

Understanding Lithium Battery Energy Density!

Defining Lithium Battery Energy Density

Battery energy density is a key term. It’s how much power you get from a battery’s size or weight. In more detail, the term “lithium battery energy density” refers to the amount of energy stored per unit volume or mass in lithium-based batteries.

High energy density, more power from a small package. Just like a strong horse pulling a big wagon. Today, a typical lithium battery might hold 150 to 200 watt-hours per kilogram (Wh/kg).

As technology advances, numbers could go higher. So, small devices can work longer without a big, heavy battery.

Why Energy Density Matters?

So, energy density is a vital factor in battery design. A higher energy density means longer-lasting power for devices. Think about mobile phones, laptops, or electric cars.

Better electric vehicles (EVs) range. All thanks to higher energy density in lithium batteries. Moreover, increased energy density leads to fewer charges, extending the battery’s lifespan.

Units for Measuring Energy Density

· Joules

Joules, a common unit for energy, plays a pivotal role in measuring lithium battery energy density. One joule equals the energy used when a one-watt electrical device is on for one second.

· Wh/kg

Often, energy density of a lithium ion battery is quantified in Watt-hours per kilogram (Wh/kg). The unit signifies the energy amount a battery can deliver per kilogram of weight. Batteries with higher Wh/kg can function longer without adding excessive weight.

· mAh/g

Sometimes, milliamp hours per gram (mAh/g) measures the energy density. It mirrors the charge a battery can hold for every gram. In simpler terms, more mAh/g means a battery can run longer on a single charge.

· kWh/L

In battery tech, Kilowatt-hours per liter (kWh/L) is a vital energy density unit. It indicates the energy a battery can dispense per its volume. Higher kWh/L reflects greater energy storing ability in a confined space.

· Joules/L

Joules per liter, another unit, relates the energy a battery can generate to its volume. More Joules/L implies the battery can discharge more energy from a given volume.

· mAh/cm³

Another significant unit, milliamp hours per cubic centimeter (mAh/cm³), relates battery charge to volume. Superior mAh/cm³ signifies batteries can hold more charge within a given volume.

· kWh/m³

Also, Kilowatt-hours per cubic meter (kWh/m³) denotes the energy output per volume unit. More kWh/m³ equals more energy from a fixed volume, leading to prolonged operation.

· BTU/lb

British Thermal Units per pound (BTU/lb) serves as another energy density measure. A battery with a higher BTU/lb can give off more heat energy for every pound of weight.

· Cal/g

Calories per gram (Cal/g) quantify energy density too. Here, higher Cal/g reflects the battery’s ability to release more heat energy per gram.

· eV/atom

Electron volts per atom (eV/atom) is an unusual energy density unit. In effect, it quantifies the energy needed to remove an electron from an atom in the battery material.

· Joules/m³

Joules per cubic meter, another variant, relates the energy a battery can dispense to its volume. Higher Joules/m³ implies the battery can discharge more energy from a given volume.

· BTU/ft³

British Thermal Units per cubic foot (BTU/ft³), is similar to BTU/lb, but relates energy to volume instead. A superior BTU/ft³ indicates a battery can generate more heat energy for every cubic foot of volume.

Components of Lithium Batteries and their role in Energy Density!

· Anode

Anodes made of graphite hold lithium ions. When a battery charges, ions move from the cathode to the anode. More ions in an anode mean higher Lithium Battery Energy Density.

· Cathode

Cathodes are often made of lithium cobalt oxide. During battery use, lithium ions travel from anode to cathode. Greater ion concentration in the cathode equates to higher energy density.

· Separator

Separators allow ions to pass while blocking electrons. Thin yet effective separators increase energy density, making batteries smaller and lighter without reducing power.

· Electrolyte

The electrolyte carries lithium ions between anode and cathode. High-quality electrolytes let more ions pass, which increases energy density. Good electrolytes are crucial for efficient lithium batteries.

· Current collector

Thin copper (anode) and aluminum (cathode) sheets collect and distribute current. Reduction in thickness results in smaller, lighter batteries with the same energy.

· Casing

Cases protect the battery components. Light, strong materials like aluminum keep the battery safe without adding much weight, maintaining high energy density.

· Safety vent

Vents prevent dangerous pressure build-up. Well-designed vents ensure safety without significant size or weight increase, preserving energy density.

· Positive terminal

Usually aluminum, the positive terminal connects the battery to the device. The size and weight of the terminal can affect the energy density of the battery.

· Negative terminal

Often copper, the negative terminal completes the battery circuit. Like the positive terminal, keeping this component light and small contributes to high energy density.

· Lithium salt

This compound in the electrolyte helps transport ions. A well-chosen lithium salt can increase ion flow and improve energy density.

· Organic solvent

This liquid dissolves the lithium salt, creating the electrolyte. The right solvent ensures a high number of ions can move, increasing the energy density of lithium ion battery.

· Conductive additives

These materials improve the electrical connection in the anode and cathode. Better connections mean more power can be stored and used, boosting energy density.

| Component | Function | Material | Safety Factor | Lifespan (Avg.) | Recyclability |

| Anode | Host for Lithium ions during discharge | Graphite, Silicon-based composites | Can overheat if not properly managed | Degrades with cycles (1000-2000) | Partially recyclable |

| Cathode | Host for Lithium ions during charge | LiCoO2, LiMn2O4, LiFePO4 | Risk of thermal runaway | Longer than anode (~2000-3000 cycles) | Highly recyclable |

| Separator | Prevents short-circuit, allows ion flow | Polypropylene, Polyethylene | Crucial for battery safety | Stable, long lifespan | Partially recyclable |

| Electrolyte | Medium for Lithium ion transport | Lithium salts in organic solvents | Flammability issues | Evolves with time & charge cycles | Challenging to recycle |

| Current collector | Collects electrons during charging/discharging | Copper (anode), Aluminium (cathode) | High electrical conductivity required | Limited degradation, long lifespan | Highly recyclable |

| Casing | Protective cover | Steel, Aluminium, Plastic | Mechanical protection | Matches battery lifespan | Highly recyclable |

| Safety vent | Allows gas escape during overheating | Various materials depending on design | Critical for safety during failure | Matches battery lifespan | Recyclability depends on material |

| Positive Terminal | Connection point for external circuit (linked to cathode) | Metallic (often Copper or Brass) | Should be resistant to corrosion | Matches battery lifespan | Highly recyclable |

| Negative Terminal | Connection point for external circuit (linked to anode) | Metallic (often Copper or Brass) | Should be resistant to corrosion | Matches battery lifespan | Highly recyclable |

| Lithium salt | Provides Lithium ions for transport in electrolyte | LiPF6, LiBF4, LiClO4 | Can degrade under high temperatures | Matches battery lifespan | Challenging to recycle |

| Organic solvent | Dissolves Lithium salt, forms part of electrolyte | EC, DMC, DEC, etc. | Flammability issues | Evolves with time & charge cycles | Challenging to recycle |

| Conductive Additives | Improve conductivity of electrodes | Carbon black, Graphene | Should not react with other components | Matches battery lifespan | Partially recyclable |

Table on Components of Lithium Batteries and their role in Energy Density!

Lithium Battery Energy Density: The Scientific Aspect

How Energy Density is Calculated?

Energy density calculation for a lithium-ion battery pivots on two factors: weight and volume. By dividing total energy storage by the weight (Wh/kg) or volume (Wh/l), one can ascertain lithium ion energy density. For instance, with 200Wh of energy in a 2kg battery, energy density equals 100Wh/kg. Higher figures signify superior energy storage capacity.

Physical Principles behind High Energy Density in Lithium Batteries

· Intercalation

Intercalation, a process in lithium batteries, enables lithium ions to be inserted into microscopic spaces in electrode materials. The more ions a material can host, the greater the energy storage. For example, graphite, an anode material, can store six lithium ions per carbon atom.

· Ion migration

Ion migration plays a crucial role. In a charged battery, lithium ions move from the anode to the cathode. During discharging, they migrate back. Faster ion movement enables more rapid charge and discharge, thereby enhancing battery performance.

· Redox reactions

Redox reactions are pivotal in lithium batteries. During charging, oxidation occurs at the anode, and reduction occurs at the cathode during discharging. The efficiency of these reactions significantly impacts battery performance.

· Overpotential

Overpotential denotes the difference between actual and theoretical voltage required to drive a reaction. Lower overpotential equates to greater energy efficiency, making it a critical aspect of high-energy lithium batteries.

· Coulombic efficiency

Coulombic efficiency represents the ratio of discharged to charged energy. High Coulombic efficiency, close to 100%, indicates an efficient battery that can fully discharge the energy stored during charging.

· Electrode surface area

A larger electrode surface area increases the space available for redox reactions, leading to enhanced energy storage. Nanostructured electrodes have been explored to maximize surface area.

· Discharge rates

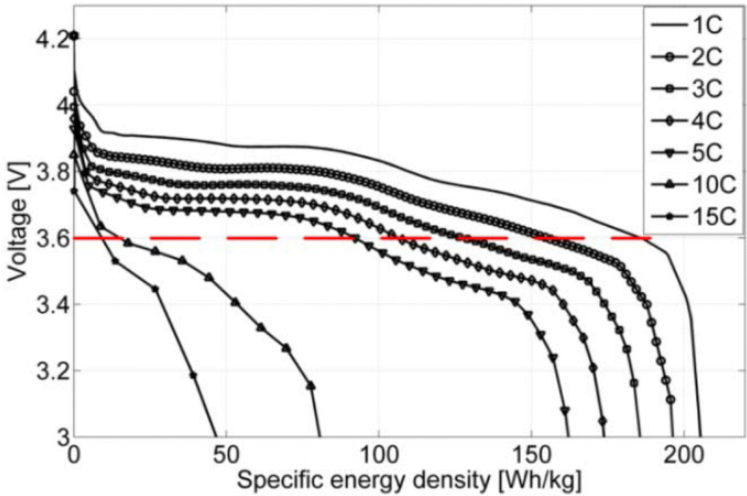

Discharge rate signifies the speed at which energy is drawn from a battery. Lower discharge rates result in higher energy efficiency, as less energy is wasted as heat.

· Cell voltage

Cell voltage defines the energy per unit charge. Higher cell voltage increases the battery’s energy density, contributing to longer battery life.

· Electrolyte conductivity

High electrolyte conductivity facilitates faster ion migration, leading to rapid charging and discharging. Advances in electrolyte design can significantly enhance this property.

· Internal resistance

Internal resistance impacts how efficiently a battery can deliver its stored energy. Lower internal resistance allows for higher energy delivery at a given discharge rate.

· Temperature effects

Temperature influences battery performance. High temperatures can speed up ion migration and redox reactions but may also accelerate unwanted side reactions, potentially damaging the battery.

· Material density

Material density of the electrodes affects the overall energy density of the battery. Higher material density can increase the energy density, but might also elevate the risk of battery failure.

Categories of Lithium Batteries and their Energy Density!

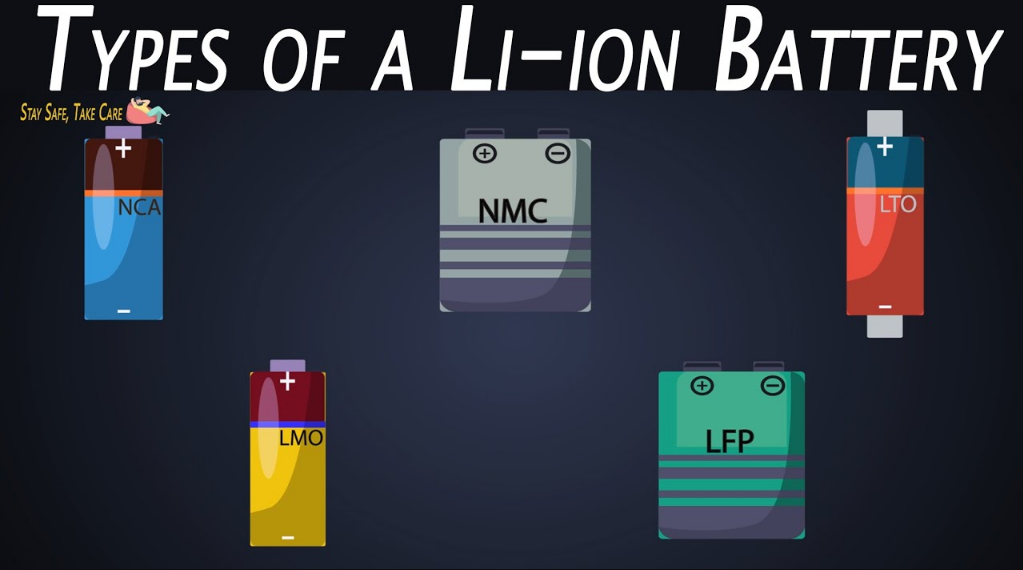

· Lithium-ion

Lithium-ion batteries are a standout for energy storage. These power packs hold about 150-265 Wh/kg of energy density. So, in just one kilogram, you get tons of power! Each cell carries 3.6 volts, so multiple cells can power bigger devices.

· Lithium-polymer

With Lithium-polymer batteries, the energy density ranges from 100-265 Wh/kg. These batteries rely on a solid polymer electrolyte. It’s different from the liquid electrolyte in lithium-ion. Energy storage is good, but not quite as high as lithium-ion.

· Lithium-iron phosphate

When looking at Lithium-iron phosphate lifepo4 batteries, the energy density decreases. They have around 90-120 Wh/kg. Lower, yes. But they make up for it with superior safety features. Overheating is less likely, making them a safer pick for many.

· Lithium-cobalt oxide

Lithium-cobalt oxide batteries push the energy density to impressive heights. These batteries can store 150-200 Wh/kg. Cobalt in the mix boosts energy storage. Yet, the trade-off is a higher risk of overheating.

· Lithium-manganese oxide

Lithium-manganese oxide batteries store 100-150 Wh/kg. By adding manganese, safety improves. This type of battery also performs well in high-temperature conditions.

· Lithium-nickel manganese cobalt oxide

The energy density here is a hefty 150-220 Wh/kg. They balance high energy storage with reasonable safety. The blend of nickel, manganese, and cobalt does the trick.

· Lithium-nickel cobalt aluminum oxide

Lithium-nickel cobalt aluminum oxide batteries store 200-265 Wh/kg. Here, aluminum is added into the mix. It enhances the stability of the battery while maintaining a high energy density.

· Lithium-titanate

The Lithium-titanate batteries trade energy density for longevity. They have a lower energy density of 50-80 Wh/kg. Yet, they can be recharged more often. Up to 20,000 times in fact!

· Lithium-sulfur

Lithium-sulfur batteries are a future hope. The energy density could be up to 500 Wh/kg! But, technical hurdles need overcoming. Scientists are working on these challenges now.

· Lithium-air

Lithium-air batteries show a lot of promise. In theory, they could reach up to 3450 Wh/kg. Lithium air battery energy density could make them future stars! Yet, there’s a lot of work to do before they become common.

Comparing Energy Density: Lithium Batteries vs. Other Batteries!

· Alkaline

Alkaline batteries provide decent energy. But, the real superstar, lithium battery energy density, surpasses them. At 150-300 Wh/kg, lithium batteries offer 3 times the power. Alkaline counterparts lag behind at a mere 100 Wh/kg.

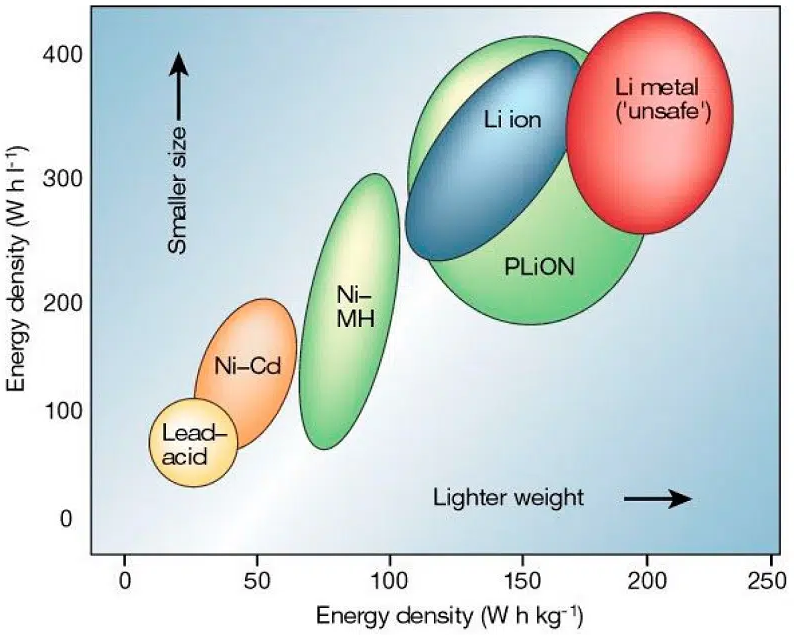

· Nickel-cadmium (NiCd)

These batteries exhibit about 40-60 Wh/kg energy density. They’re outpaced by lithium batteries. Storing more power, lithium batteries drive devices longer.

· Nickel-metal hydride (NiMH)

Greater than NiCd, NiMH’s energy density touches 60-120 Wh/kg. Lithium batteries, though, remain unmatched in power, showcasing their dominance.

· Lead-acid

Though tried and true, lead-acid batteries show a low energy density of 30-50 Wh/kg. In contrast, lithium batteries excel, pushing the envelope with their higher density.

· Zinc-carbon

Holding only 35-55 Wh/kg energy density, zinc-carbon batteries trail far behind lithium batteries. Lithium batteries assure longer usage time, thanks to their superior power retention.

· Silver-oxide

Better than many, silver-oxide batteries hold an energy density of 130-200 Wh/kg. Yet, lithium batteries still rise above them, offering an unbeatable energy storage capability.

· Sodium-ion

Presenting an energy density of 90-120 Wh/kg, sodium-ion batteries show promise. But, lithium batteries carry the day with their higher energy reserves.

· Zinc-air

Zinc-air batteries possess an impressive 300 Wh/kg energy density. Nonetheless, the high-performing lithium batteries remain a strong contender in the energy density race.

· Fuel cells

Displaying an immense 600-1000 Wh/L energy density, fuel cells show strength. Even so, lithium batteries bring benefits like portability and versatility.

Gravimetric Energy Density Vs. Volumetric Energy Density in Lithium Batteries!

Understanding Gravimetric Energy Density

Look at lithium batteries, powerful and light. Gravimetric energy density, in short, is power per weight. High numbers mean more energy, less weight. For example, lithium batteries boast a robust 150 to 200 Wh/kg.

Here, ‘Wh’ means Watt hours, ‘kg’ denotes kilogram. Batteries with high gravimetric energy density are desirable for mobile devices.

Laptops, smartphones, electric cars, all benefit from them. So, next time, remember the power-to-weight ratio. What is the energy density of a lithium ion battery? Now, you’ve got the answer.

Understanding Volumetric Energy Density

Let’s jump into volumetric energy density. It’s all about energy stored per unit volume. For lithium batteries, this stands at 250 to 620 Wh/L. Here, ‘Wh’ is Watt hours, ‘L’ represents liters.

A high volumetric energy density means more power in less space. This factor is crucial in compact, space-constrained applications. Consider wireless earbuds, for instance.

A tiny battery, yet delivers hours of audio playback. Remember, what is lithium battery energy content? It’s all about how much power can be stored in given space.

Comparing Gravimetric and Volumetric Energy Densities

· Power-to-weight ratio

The power-to-weight ratio is key for understanding lithium battery energy density. Higher values mean better performance. A battery of 150 Wh/kg has a robust output. However, smaller batteries often have superior ratios.

· Energy-to-weight ratio

In lithium batteries, the energy-to-weight ratio is paramount. Top units boast ratings of 250 Wh/kg. A battery with 200 Wh/kg will show high energy density.

· Power-to-volume ratio

The power-to-volume ratio tells about battery power per size. Values of 600 Wh/L are deemed superb. Still, ratios vary with the battery’s form.

· Energy-to-volume ratio

The energy-to-volume ratio for a lithium battery is significant. Standard batteries show rates of 700 Wh/L. Such figures prove that small-sized batteries can hold immense energy.

· Battery size

Battery size impacts energy density. A 18650 battery pack measures 18mm by 65mm. The smaller, the better. Small units have high energy density. Size reduction is a key goal for lithium battery manufacturers.

· Battery weight

The weight of a lithium battery plays a crucial role. A 46 g battery offers a good balance of power and weight. Lightweight units offer high energy density. A lighter battery can store more energy per kilogram.

· Charge retention

Charge retention defines battery health. A top-notch unit keeps 80% charge after 500 cycles. So, better charge retention implies high energy density. Lithium batteries with high charge retention ensure prolonged use.

· Fast charging

Fast charging is a vital attribute for lithium batteries. Units capable of 15-minute charge cycles are highly desirable. Fast charging does not reduce energy density. Quick charging ability doesn’t compromise stored energy.

· High capacity

High capacity lithium batteries are sought after. Capacities of 3500 mAh show excellent energy storage. High capacity correlates with high energy density. So, more capacity equals more stored energy.

· Longevity

Lithium batteries with long life are preferred. Some survive up to 3000 cycles. Long-lasting batteries maintain energy density over time.

· Performance

Performance is vital for lithium batteries. A unit operating at -20°C and 60°C demonstrates superior capabilities. Good performance assures energy density maintenance.

· Cost

Cost factors into lithium battery adoption. Units priced at $100 per kWh are competitive. Lower cost encourages wider use.

Energy Density of Lithium-ion Battery: A Detailed Analysis!

Factors Affecting Energy Density of Lithium-ion Batteries

· Electrode material

Electrode material, indeed, plays a vital role in what is energy density in battery. With lithium-ion batteries, energy storage hinges largely on the material used.

For instance, lithium cobalt oxide, used in phones, can store up to 150Wh/kg. In contrast, lithium manganese oxide, ideal for power tools, holds about 100Wh/kg.

· Cathode thickness

A thick cathode promises high energy density. However, it also increases lithium-ion path length. Resultantly, battery resistance goes up, while discharge rate declines. The objective is to achieve an optimal cathode thickness for balanced battery performance.

· Anode-to-cathode ratio

Anode and cathode balance is crucial. Too much cathode, lithium-ions get wasted. Excessive anode leads to lithium plating. Maintaining an appropriate anode-to-cathode ratio safeguards battery efficiency and longevity.

· Cell temperature

Heat affects a lithium-ion battery’s energy density. Elevated temperature expedites chemical reactions, enhancing energy release. Yet, excessive heat can harm the battery’s structure, reducing overall energy density.

· Discharge rate

Energy density relates to discharge rates, too. High discharge rates can cause rapid capacity loss, effectively diminishing energy density. Devices with high power needs may need larger, denser batteries.

· Electrolyte composition

The electrolyte’s role is crucial in lithium-ion batteries. A well-optimized electrolyte composition can bolster energy density. However, finding the right electrolyte mixture, one that balances conductivity and stability, can be challenging.

· Electrode porosity

Electrode porosity can affect energy density. Higher porosity means more space for lithium-ion movement, potentially increasing energy density. Yet, high porosity can also raise the risk of mechanical failure.

· Cell voltage

The voltage across a cell impacts energy density. Higher voltages enable more energy storage. Yet, voltage increases must be carefully controlled. Too much can lead to battery damage.

· Cycle life

Each charge-discharge cycle can cause slight capacity loss, reducing energy density over time. Designing a lithium-ion battery involves a trade-off between energy density and cycle life.

· Aging

With aging, battery capacity and, consequently, energy density decline. Material deterioration and the formation of solid-electrolyte interface layers contribute to this aging effect.

· Manufacturing precision

Precision in manufacturing also affects energy density. Any flaw, like impurities in the electrode material or inaccuracies in electrode thickness, can diminish energy density.

· Safety features

While not directly linked to energy density, safety features are imperative. These can limit the maximum voltage and temperature, indirectly affecting the battery’s energy density.

How to Increase the Energy Density of Lithium-ion Batteries?

· Material innovation

Focusing on material innovation, scientists enhance the Lithium Battery Energy Density. Nickel, cobalt, and manganese form the popular NCM blend. This blend, upgraded to NCM 811, boosts the energy output. On the downside, stability becomes a challenge.

· Electrolyte improvement

With electrolyte improvement, energy density sees an upturn. Utilizing organosilicon compounds, scientists aim to create safer batteries. Moreover, such compounds prove resistant to decomposition at higher voltages.

· Cell design optimization

Optimizing cell design plays a crucial role too. By increasing electrode thickness, energy density improves. Yet, the balance with power output remains a constant struggle.

· Advanced manufacturing

Advanced manufacturing techniques, such as dry room fabrication, show promise. Precise control over the battery’s construction leads to a more stable structure.

· Thermal management

Thermal management is integral to battery performance. Heat dispersion methods, like phase change materials (PCMs), control temperature. With optimized temperature, batteries perform at peak capacity.

· Better separators

Better separators can boost energy density. Using ceramic-coated separators offer multiple benefits. They enhance safety and allow for higher energy density.

· Advanced cathodes

Advanced cathodes are crucial in the energy density equation. Lithium-rich NMC cathodes show potential for higher energy storage. These cathodes, however, need further exploration due to stability issues.

· Nanostructured anodes

Incorporating nanostructured anodes can make a difference. Silicon-based anodes hold more lithium ions than graphite. Yet, volume changes during charging pose a challenge.

· Solid electrolytes

Using solid electrolytes, experts aim to develop safer, higher energy batteries. The solid-state battery vs lithium-ion energy density debate focuses on these. Solid-state batteries present higher energy density, but require more research.

· High voltage cells

High voltage cells raise the energy density bar. Cells operating above 4.3V promise improved energy output. Unfortunately, such cells may degrade faster, demanding cautious handling.

· Enhanced safety features

Enhanced safety features contribute to improved energy density. By implementing features like thermal fuses, battery safety increases. In turn, this allows for greater energy density.

· Controlled discharge rates

Controlled discharge rates matter. With slower discharge rates, a battery can store more energy. Consequently, energy density sees a boost. Each innovation brings closer the goal of increased Lithium Battery Energy Density.

Advanced Concepts: Theoretical Energy Density of Lithium Batteries!

Understanding Theoretical Energy Density

In theoretical terms, the energy density of lithium batteries is a crucial factor. Maximum energy density sits at 3860 watt-hours per kilogram (Wh/kg). To comprehend, imagine a small battery powering a large machine for hours. It’s all about how much energy can be stored in a given mass.

Importance of Theoretical Energy Density in Research

· Material science

In material science, optimizing the lithium battery energy density becomes pivotal. Higher density means more power per unit weight. To boost density, scientists are exploring materials such as lithium-metal and silicon-based anodes.

· Nanoengineering

On a tiny scale, nanoengineering plays a significant part. Lithium battery energy density can be increased by designing nanoscale structures. Such structures offer greater surface area for chemical reactions, yielding more power.

· Solid-state physics

Solid state battery energy density vs lithium ion is a hot research topic. Solid state batteries offer more safety and higher density, thanks to their solid electrolyte. However, manufacturing challenges remain.

· Electrochemistry

In electrochemistry, experts are looking at lithium’s reactions with other materials. Every reaction alters the lithium battery energy density. For instance, lithium-air batteries hold promise for very high energy densities.

· Computational modeling

Simulating the behavior of lithium-ion batteries on a computer helps scientists. With this, they can tweak parameters to increase lithium battery energy density without making a physical prototype.

· Energy storage

High lithium battery energy density is key for energy storage. More energy per unit weight means longer backup power. Especially for renewables like solar and wind, storage is crucial.

· Power electronics

In power electronics, lithium battery energy density impacts device efficiency. Higher density leads to less weight, longer runtimes, and quicker charging, enhancing user experience.

· Automotive applications

For electric vehicles (EVs), lithium battery energy density matters greatly. High density means more range for EVs, making them a viable alternative to petrol cars.

· Grid storage

High lithium battery energy density is vital for grid storage. With greater density, grids can store more energy, improving the reliability of power supply during peak demand.

· Portable electronics

Portable electronics like laptops and phones benefit from high lithium battery energy density. High density translates to longer battery life, enabling users to work and play longer.

· Space exploration

For space missions, every gram counts. High lithium battery energy density ensures space probes and rovers have enough power to perform their tasks without adding much weight.

· Renewable energy

In the context of renewable energy, lithium battery energy density is crucial. Higher energy density enables more efficient storage of energy from intermittent sources like wind and sun. Furthermore, the role of sodium vs lithium battery energy density is being explored for more sustainable and accessible solutions.

Understanding Energy Content in Lithium Batteries!

Meaning of Energy Content in Lithium Batteries

In the realm of batteries, energy content signifies stored power. To discuss specifically, Lithium Battery Energy Density involves this capacity.

High energy density means more power in less space. Energy content and density play a crucial role in modern power needs, where compact, long-lasting batteries remain paramount.

Relation between Energy Content and Energy Density

· Battery capacity

The energy content of a battery hinges on capacity. More capacity denotes longer power output. As a rule, a high-capacity lithium battery has high energy density. However, other factors too shape this density.

· Battery size

The size of a battery affects energy content. Tiny cells pack in less energy. For larger cells, energy content and density climb. In other words, a large lithium battery can store more power.

· Battery weight

Mass also influences energy content. A battery may be large, but if it’s light, the energy content might be lower. Consequently, a battery’s energy density ties closely to its weight.

· Operating temperature

Temperature can shift a battery’s energy content. In general, extreme cold or heat can drop the energy density. So, lithium battery energy density is ideal at room temperature.

· Discharge rates

Discharge rates also connect to energy content. Swift discharge can cause energy density to dip. Slower discharge rates favor higher energy content.

· Cycle life

The lifespan of a battery influences energy content. With each charge and discharge cycle, the energy content can lessen. Lithium batteries with long cycle lives retain more energy density.

· State of charge

The state of charge impacts energy content. A fully charged battery has more energy density than a half-charged one.

· Depth of discharge

How much a battery discharges can affect energy density. For example, if a battery often discharges fully, its overall energy content may fall. So, discharge depth can shift energy content over time.

· Cell voltage

Voltage also factors into energy content. A higher voltage lithium battery can hold more energy, leading to a boost in energy density.

· Aging effects

As batteries age, they lose some energy content. Old lithium batteries may not hold as much charge as when they were new, leading to lower energy density.

· Energy efficiency

Efficiency reflects how well a battery converts stored energy into power. Higher efficiency means more of the stored energy can be used, which can increase energy density.

· Charge retention

Charge retention relates to a battery’s ability to hold charge over time. Better charge retention means higher energy content and density. So, lithium batteries with good charge retention offer better energy density.

Optimizing Energy Density in Lithium Batteries!

Techniques to Improve Energy Density

· Material Optimization

With lithium sulfur battery energy density, there is a need to optimize materials. Lithium, with a high electrochemical potential, is a vital metal. By refining materials like cathodes, experts enhance energy density. Using sulfur, for example, leads to higher energy capacity.

Lithium and sulfur form a strong duo in energy storage. Also, employing better separators can increase battery capacity. Separator technology aids in maintaining battery stability.

· Cell Design

Designing lithium cells is a nuanced task. Precision is key to achieve superior lithium battery energy density comparison. A battery’s layout greatly influences energy density. Different cell structures like cylindrical, prismatic, and pouch have their pros and cons.

The cylindrical model, used in electric vehicles, excels in thermal management. The prismatic design, preferred for its compact size, saves space. Pouch cells are flexible and lightweight, ideal for portable devices.

· Advanced Manufacturing

For improved lithium polymer battery energy density, advanced manufacturing practices are crucial. High-precision machinery ensures a flawless manufacturing process. The application of nanotechnology improves the overall battery performance.

It aids in enhancing the rate capability and capacity of batteries.

Efficient manufacturing processes also result in less material wastage. This leads to an increase in the battery’s energy density.

· Electrolyte Tuning

Electrolyte tuning is a prominent factor affecting lithium metal battery energy density. The electrolyte, a conductive medium, allows the flow of ions between the cathode and anode. An ideal electrolyte will have high ionic conductivity and be stable under high voltages. Fine-tuning the electrolyte composition can greatly boost a battery’s energy storage capacity.

· Temperature Management

Battery performance is closely linked to temperature. Keeping lithium batteries within their optimal temperature range boosts energy density. Cold temperatures can cause a reduction in performance, while high temperatures may lead to degradation.

Maintaining an optimal temperature range ensures longer battery life and optimal energy density. Thermally conductive materials and cooling systems are two techniques used for temperature management.

· Safety Enhancements

Safety measures in lithium batteries contribute to energy density. Safety technology prevents overheating and leakage, preserving battery life. Devices like safety vents, thermal interrupts, and pressure relief valves prevent catastrophic failures.

A battery management system (BMS) monitors and controls battery conditions. These enhancements ensure energy efficiency and extend the lifespan of the battery, thus improving energy density.

· Fast charging

Fast charging serves as a crucial technique. Swift energy transfer raises the Lithium Battery Energy Density. Batteries fill up in minutes, not hours. Shorter charging periods reduce battery stress, boosting density. Technology like Direct Current Fast Charging (DCFC) has revolutionized energy storage. Rapid charging methods escalate energy densities in lithium batteries.

· Cycle life extension

Emphasizing on cycle life extension significantly improves energy density. Longer battery cycles equate to improved density. Techniques such as Battery Management System (BMS) help extend cycles. BMS keeps track of voltage levels, temperature, and current.

· Nanoengineering

Nanoengineering can immensely augment energy density. Nano-sized lithium ions mean denser energy storage. These tiny particles can pack more power in less space. Nanoscale designs offer increased surface area for reactions, which in turn boosts energy storage.

· Solid electrolytes

Transitioning to solid electrolytes proves beneficial for enhancing energy density. They allow faster ion movement and better safety. Solid-State Batteries (SSBs) employ these electrolytes, providing higher energy density. SSBs present an innovative approach for advancing lithium battery capabilities.

· High voltage cells

Adoption of high voltage cells is another tactic for energy density enhancement. Higher voltage levels can store more energy. Batteries like Lithium Nickel Manganese Cobalt Oxide (NMC) cells offer 4.7 volts, elevating energy density. High voltage cells promise superior energy storage capacities.

· Advanced separators

Utilizing advanced separators supports lithium battery energy density improvement. These separators prevent short-circuits and aid ion transfer. Innovative materials like ceramic-coated separators elevate safety and performance. Advanced separators play a significant role in elevating lithium battery energy densities.

Challenges in Optimizing Energy Density

· Material constraints

Material constraints shape the lithium iron phosphate battery energy density. Lithium, cobalt, and graphite are vital in battery construction. Short supply of these elements can impact battery performance. Careful selection of raw materials is key.

Their quality affects the energy stored in each battery cell. High-grade materials result in higher energy density. Yet, securing such materials is a global challenge.

· Manufacturing precision

Manufacturing precision is central to optimizing lithium battery energy density. Battery components, such as anode, cathode, and electrolyte need precise alignment. Each nanometer deviation can degrade battery performance.

Manufacturing facilities strive for absolute precision. Yet, maintaining this precision across millions of battery units is a daunting task. Such challenges add to the complexity of enhancing lithium ion energy density per kg.

· Safety risks

Safety risks associated with lithium batteries need attention. Lithium is a reactive metal. Mishandling can lead to fires or explosions.

Battery construction thus needs stringent safety protocols. Safety measures often limit the energy that can be packed into each cell. This inherent trade-off between safety and lithium ion energy density over time is a core challenge.

· Battery lifespan

Battery lifespan is another factor. A battery’s life declines with every charge-discharge cycle. Over time, chemical changes within the battery reduce its energy density.

The capacity of lithium batteries to store energy dwindles over the years. Battery longevity is a pivotal issue in maximizing lithium battery energy density.

· Thermal management

Thermal management is key in optimizing lithium battery energy density. Heat affects battery performance. Too much heat can cause a battery to fail. Effective heat management is vital to maintain battery life and performance. Yet, designing effective cooling systems for batteries remains a tough challenge.

· Charging speed

Charging speed also impacts lithium battery energy density. Fast charging can strain the battery. It causes lithium ions to pile up, affecting battery health. A balance between charging speed and battery longevity is essential.

· Cost considerations

In optimizing Lithium Battery Energy Density, cost considerations play a huge role. High-performance materials for cathodes and anodes may cost more. Lower cost, however, might reduce density, hampering energy storage.

· Recycling issues

Next, consider the challenge of recycling. Lithium batteries contain valuable materials. Recycling can retrieve 95% of lithium, cobalt, nickel, and others. Still, current recycling methods are inefficient, contributing to waste and increased demand for raw materials. Effective recycling methods need further development.

· Supply chain

Sourcing raw materials for lithium batteries can pose challenges. These materials, such as lithium, cobalt, and nickel, are found in specific global regions. Any disruption in their availability affects battery production and ultimately, energy density.

· Environmental impacts

Furthermore, environmental impacts matter. Mining and refining of raw materials for lithium batteries cause significant environmental harm. This includes water pollution and deforestation. Efforts to minimize environmental damage must go hand-in-hand with density optimization strategies.

· Regulatory standards

Regulatory standards also have an influence. Standards such as the UN38.3 for the transport of lithium batteries, set by the United Nations, impacts design and testing. Adherence to such standards may limit potential enhancements to energy density.

· Technology readiness

Technology readiness is a vital factor. Current technology may not fully support density improvements. Research is ongoing, with progress in solid-state batteries and nanotechnology. Still, these technologies are in early stages, their practical application remains uncertain.

Understanding Energy Storage Capacity in Lithium Batteries!

How Much Energy Can a Lithium Battery Store?

An average lithium-ion battery volumetric energy density hovers around 700 watt-hours per liter (Wh/L). A laptop battery, measuring 60 Wh, might occupy about 60 cubic cm.

That’s a lot of power in a small space! Yet, the lithium-ion battery theoretical energy density soars even higher – 2,700 Wh/L. There’s room to make lithium batteries store even more energy!

Factors Influencing Energy Storage Capacity in Lithium Batteries

· Material properties

Lithium batteries utilize various materials, impacting energy density. Electrode materials, for instance, like cobalt or manganese, affect energy storage. Better materials can improve the lithium-ion battery theoretical energy density.

· Cell design

The design of a battery cell influences energy density. For instance, in cylindrical cells, there’s more unused space. On the contrary, pouch cells allow for maximum space use, boosting energy density.

· Battery size

The size of a lithium battery dictates how much energy it can store. In simple terms, bigger batteries can store more energy. Keep in mind though, bigger isn’t always better. It can make the device bulky and unwieldy.

· Battery weight

Weight plays a role in energy density. Lighter batteries often yield higher energy density. It means you get more power without carrying extra weight.

· Operating temperature

Temperature affects energy density. At high temperatures, batteries can deliver more power. However, they also wear out faster. Optimizing temperature helps balance energy output and battery lifespan.

· Discharge rates

The rate at which a battery releases energy impacts its energy density. Faster discharge rates can deliver high power but drain the battery faster. So, managing discharge rates is key to improving energy density.

· Cycle Life

Every time a lithium-ion battery goes from full to empty, that’s a cycle. So, more cycles mean a longer life. But, here’s a key point: each cycle can lessen energy storage. For example, a battery might hold 1000mAh on day one, but only 950mAh after 500 cycles.

· Aging Effects

Batteries don’t stay young forever. Just like people, batteries get older. As batteries age, internal parts can break down. The anode, cathode, and electrolyte can all be affected.

What does this mean for energy density? Well, an older battery might not hold as much energy. For example, a lithium-ion battery volumetric energy density of 700Wh/l could drop to 650Wh/l over a few years.

· State of Charge

Charge level can alter energy storage. A battery that’s 100% full might hold more energy than one at 50%. Also, keeping batteries at full charge too often can harm energy density over time. For example, a battery with a high lithium-ion battery theoretical energy density might lose capacity if always kept full. So, remember to charge batteries wisely.

· Depth of Discharge

Discharge means using up battery power. Depth of discharge (DoD) is how much of that power gets used. For example, using 50% of a battery’s power equals a 50% DoD. Deeper DoD can hurt energy storage. Keeping DoD low can protect a battery’s energy density.

· Cell Voltage

Voltage in a battery cell can shift energy density. For instance, a high voltage can mean more energy storage. But, be careful, because too high voltage can lead to battery damage. Also, cell voltage can change with use. Over time, voltage drops can lead to lower energy density.

· Energy Efficiency

Finally, efficiency is vital for energy storage. High efficiency means less wasted energy. For example, an efficient battery could have 90% of its energy go to useful work. The other 10% might turn into heat. So, a battery with better efficiency can offer higher energy density.

Energy Density Measurements in Lithium Batteries!

· Gravimetric Analysis

When assessing lithium ion battery energy density wh/kg, experts rely on gravimetric analysis. By measuring mass, one can determine the energy per kilogram.

An average lithium battery can pack about 150 to 200 watt-hours per kilogram. This technique, while simple, offers valuable insights into the performance of these energy-storing cells.

· Volumetric Analysis

Volumetric analysis is another crucial measure. Instead of mass, it focuses on volume. Here, energy density is calculated per unit volume. A standard lithium-ion cell can contain around 250 to 620 watt-hours per liter. This information helps understand how much energy can be stored in a given space.

· Spectroscopic Methods

To further probe into a lithium battery’s energy density, spectroscopic methods come into play. Spectroscopy enables analysis of chemical composition. Material quality plays a crucial role in energy density. A well-composed lithium-ion battery could indeed provide higher energy storage capacity.

· Electrochemical Tests

Additionally, electrochemical tests provide data about battery performance. A good lithium-ion battery can charge quickly, hold its charge over time, and discharge efficiently. Through this, one can gauge how the lithium ion battery energy density changes over time.

· Thermal Analysis

Thermal analysis, a valuable tool, monitors battery behavior under different temperatures. Lithium batteries can lose capacity in extreme temperatures. So, keeping an eye on thermal properties supports the optimization of energy density.

· Microscopy

Microscopy delivers a closer look at a battery’s physical structure. The structure greatly impacts the lithium ion battery energy density vs gasoline comparison. While gasoline holds more energy per liter, lithium-ion batteries are catching up, thanks to improvements in cell design.

With each of these methods, experts can fine-tune lithium battery energy density, ensuring optimal performance.

· X-ray techniques

X-ray techniques offer valuable data about lithium battery energy density. Bright X-rays peek into lithium batteries, showing the structure of the components. They expose the arrangement of lithium ions in the active material, boosting understanding of the energy capacity.

The figure may reach around 250 watt-hours per kilogram (Wh/kg). Unique X-rays give out reliable data. Such information steers clear of uncertainty, offering a clear picture of battery potential.

· Battery cyclers

Battery cyclers present another angle to understanding lithium battery capacity. Through repeated charging and discharging cycles, you get an energy capacity reading.

For instance, a reading might be 150 millijoules per kilogram (lithium ion battery energy density mj/kg). Such data, coupled with time, presents the life expectancy of the battery. Battery cyclers, hence, act as important tools in the study of energy density.

· Impedance spectroscopy

Impedance spectroscopy takes the investigation of energy density a step further. This method probes the battery’s inner resistance, highlighting the obstruction to ion flow.

A battery with low resistance means more ions are moving. This implies more energy, enhancing the energy density value. An average lithium ion battery energy density kwh/kg figure may be 0.2. Each reading from impedance spectroscopy is crucial for battery optimization.

· Differential scanning calorimetry

Differential scanning calorimetry (DSC) brings thermal properties into play. A DSC test measures heat flow related to the battery reactions. By knowing the heat flow, one understands the reactions better. This method can unveil the lithium battery energy content meaning. For instance, less heat indicates efficient reactions, suggesting a higher energy density.

· Atomic force microscopy

Atomic force microscopy (AFM) presents the surface at a microscopic level. Tiny probes scan the battery surface, detailing every nano-feature.

In the lithium battery context, a smoother surface implies easier ion movement. AFM opens up new dimensions in studying battery performance.

· Neutron scattering

Neutron scattering gives a deep dive into lithium-ion behavior. Neutrons can penetrate dense materials, revealing ion positions. This method can show where lithium ions are, indicating the level of energy use. Efficient ion use suggests a higher energy density, offering a full image of the battery’s potential.

| Criteria | Gravimetric Analysis | Volumetric Analysis | Spectroscopic Methods | Electrochemical Tests | Thermal Analysis | Microscopy |

| Energy Density | Measures in Wh/kg | Measures in Wh/L | N/A | Wh/kg, Wh/L | N/A | N/A |

| Method Principle | Mass change | Volume change | Emission/absorption | Redox reactions | Heat change | Image analysis |

| Accuracy | High | Medium | High | High | High | Medium |

| Equipment Cost | Low | Low | High | High | Medium | High |

| Time Requirement | Medium | Medium | High | High | Medium | High |

| Sample Preparation | Medium | Medium | High | High | Medium | High |

Table on Energy Density Measurements in Lithium Batteries!

Energy Density in Lithium Batteries: Addressing the Challenges!

· Safety concerns

Here’s a tricky part. Energy density of a lithium battery means the ability to store more power. But, higher energy density can lead to safety risks. Overheating can happen.

So, management systems are vital. They prevent things like short circuits and high temperatures. The lithium air battery energy density is high but needs careful handling.

· Material scarcity

Energy density depends on materials used. The li battery energy density needs lithium. It’s a rare metal. Earth has only a limited amount. Scarcity of lithium can drive costs up. It’s essential to find alternate materials or reuse old batteries.

· Manufacturing costs

The li air battery energy density is high. But, producing such batteries is costly. To store more energy, we need better materials. These are often expensive. Affordable batteries can boost the adoption of electric vehicles. That would cut down the use of fossil fuels.

· Battery lifespan

A battery’s life is vital. How long a battery lasts affects the energy density. If a battery lives longer, the energy density of lithium polymer battery remains stable. A long-lasting battery can store and supply power for a more extended period.

· Fast charging

Charging speed is crucial for battery users. But, how much energy can a lithium battery store affects this. Fast charging requires high energy density. Yet, quick charging can also heat up batteries. That reduces their lifespan.

· High temperature operation

Batteries often get used in harsh environments. The energy density of lithium ion battery vs lead acid is much higher. But, lithium batteries may not perform well at high temperatures.

So, finding a balance is crucial. Even the energy density of lithium-ion battery vs gasoline is a hot topic. Gasoline works well at high temperatures. Lithium batteries need to match this.

· Cold temperature performance

At freezing conditions, the energy density of lithium-ion battery mj/kg lessens. In other words, less energy gets stored per unit weight. At -20°C, the output capacity drops by about half.

Here’s a solution – heated battery packs. Battery makers pre-warm the lifepo4 cells, enhancing energy output. Despite low temps, lithium batteries maintain efficiency.

· Recycling hurdles

Every lithium battery possesses a finite life. Upon exhaustion, battery disposal turns critical. Yet, recycling the energy density of lithium-ion battery in joules poses a challenge.

Processing lithium batteries requires unique machinery. With high capital costs, such facilities are scarce. Innovation in recycling tech, however, can tackle this issue.

· Grid storage

Storing electricity on a large scale needs high energy density of lfp batteries. However, balancing energy storage, discharge rates, and lifecycle involves complexity. Battery management systems help control charge cycles and battery health, optimizing grid storage.

· Vehicle electrification

The race for the best energy density lithium battery powers the electric vehicle industry. More energy stored per kilogram means longer drives. The energy density diesel vs lithium-ion is still a gap. Yet, ongoing research promises future advancements.

· Portable electronics

Small gadgets like smartphones crave high lithium polymer battery energy density. More energy per weight allows devices to run longer. While improvements continue, challenges persist. Overheating and short lifespan issues still require resolution.

· Space applications

Spacecraft require batteries with an optimum lithium-ion battery energy density vs gasoline. With each gram of weight crucial, the current lithium-ion battery energy density is a key concern. But, space demands robustness and longevity. The lithium iron phosphate battery energy density is a possible solution, offering better stability.

Conclusion

As a closing note, lithium battery energy density stands at the forefront of battery performance determinants. The burgeoning demand for these power units necessitates the invention of innovative materials and methodologies to augment energy density.

Such advancements are imperative to spearhead the future trajectory of electric vehicles, renewable energy sectors, and a host of other domains dependent on lithium batteries. For more, visit BuzzUp!